The mining industry is entering a transformative era as it evolves from a traditionally manual and labor-intensive field into a tech-forward powerhouse fueled by automation, data, and advanced materials. To further this change, mining operations need smarter solutions that enhance efficiency, safety, and sustainability.

Two major trends are shaping the new direction of mining. One is the rise of “smart mining” technologies and the other is increased need for well services in exploration and operations. Together, these forces are driving a notable increase in demand for specialized components, such as Swift Glass’s temporary tempered glass well plugs. These advanced tools are uniquely designed to meet the challenges of modern mining head-on. Keep reading to learn more.

A Surge in Well and Drilling Services

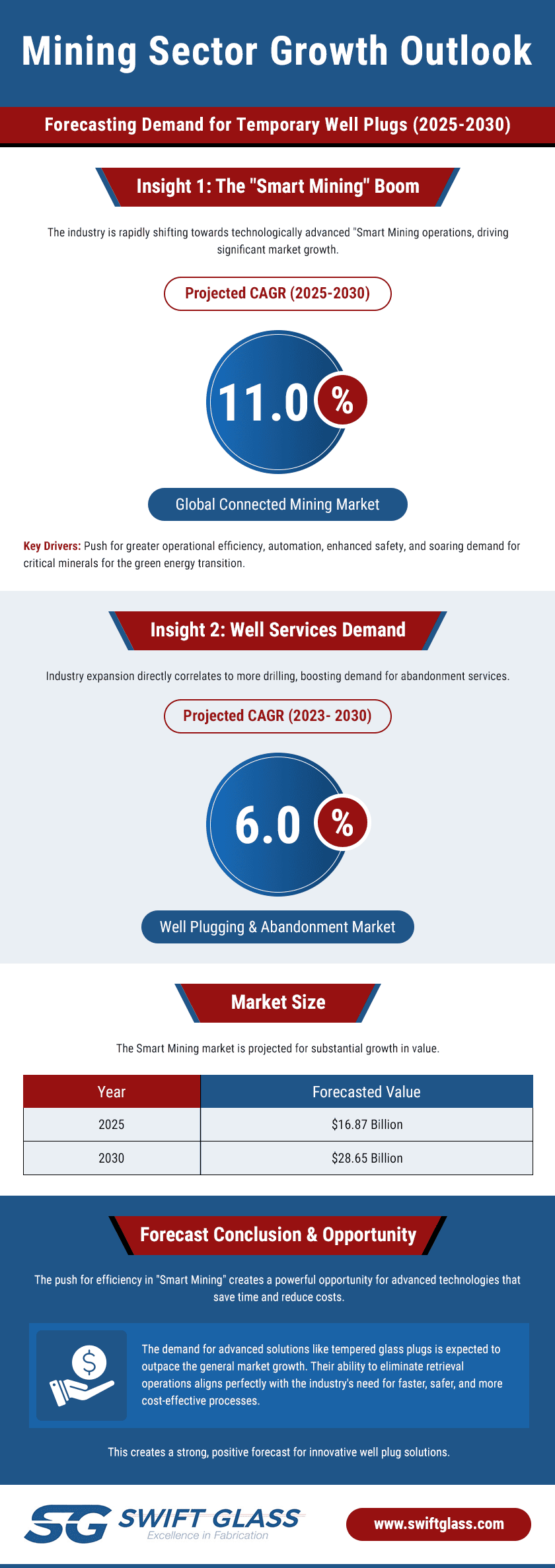

As global demand for minerals rises, mining operations are expanding in both scope and sophistication. In fact, the mining industry as a whole is projected to grow at a rate of 5.7% CAGR by 2030. This growth directly translates into more ground-level activity, particularly drilling wells for exploration, dewatering, and geotechnical evaluation.

All wells eventually need to be temporarily or permanently sealed. This means well abandonment services are an essential part of the mining life cycle. The market for well plugging and abandonment services is forecast to grow at a steady CAGR of around 6.0% through 2030, according to GMI Research. While much of this growth pertains to permanent closures, it also reflects an increased demand for temporary well management solutions that support modern, staged project planning.

The Macro View: The Smart Mining Revolution Is Here

“Smart mining” refers to integrating technologies, such as AI, IoT, cloud-computing, and real-time analytics, throughout the mining value chain. It’s not merely a buzzword. Smart mining represents a seismic shift toward increased automation, cost reduction, and enhanced worker safety.

The global connected mining market is projected to grow at a compound annual rate of 11% between 2025 and 2030, according to Grand View Research. Three primary forces are propelling this growth:

- Efficiency Mandates. Declining ore grades and rising operational costs demand faster and leaner processes.

- The Green Energy Transition. The urgent global push for electrification and renewable technologies creates an unprecedented appetite for critical minerals like lithium, cobalt, and rare earth elements.

- Regulatory and Safety Pressure. Companies are under increasing pressure to reduce workplace hazards and comply with evolving environmental and safety standards.

These drivers are accelerating the adoption of high-tech tools and processes across the mining landscape. But they also create secondary pressures: legacy equipment and outdated processes, such as mechanical well plugs that require costly and risky retrieval, can become major obstacles to efficiency.

Why Advanced Plugs Are Set to Outperform Old Designs

The convergence of smart mining’s explosive 11% projected growth and the 6% forecast for well abandonment services reveals a significant opportunity well plug production and sales. But there is a potential bottleneck: traditional mechanical plugs often require retrieval processes or drilling to remove, which means extended downtime, increased labor costs, and heightened safety risks.

Swift Glass’s tempered glass plugs are a strategic alternative. Created through a precise thermal glass tempering process, these plugs are engineered to withstand the extreme temperatures and pressures of downhole environments. They also incorporate a controlled shatter design that allows them to break apart cleanly when triggered. As a result, these advanced plugs eliminate the need for removal.

Temporary tempered glass plugs have a number of benefits for mining and well abandonment operations, including:

- Less unplanned downtime.

- Enhanced worker safety.

- Streamlined planning for multi-stage wells.

- Lower overall project costs.

Proven effective in oil, gas, and petrochemical applications, these plugs are now positioned as a key enabling technology for mining operations that are pursuing faster, smarter workflows. And because they directly support the goals of smart mining, their market growth is likely to outpace even the baseline 6% CAGR seen in the broader well services category.

Meeting the Moment with Advanced Materials

The need for smarter well management doesn’t end with digital dashboards and predictive analytics. Physical components like well plugs must evolve in tandem with software and computer-driven tools and equipment. To stay competitive, mining operations need tools that match the speed, safety, and sustainability standards set by smart mining principles.

At Swift Glass, we’ve developed tempered glass for the mining industry and controlled shatter glass well plugs specifically for this future-focused approach. These plugs offer:

- High strength-to-weight ratio.

- Predictable, safe disintegration.

- Compatibility with aggressive downhole conditions.

- Simple deployment with no retrieval required.

Get Ahead with Solutions from Swift Glass

The data tells a compelling story: the mining industry is growing fast, and it’s getting smarter. As the sector embraces automation and AI, the demand for intelligent, efficiency-boosting components is skyrocketing.

For mining companies ready to step into the future, now is the time to act. Contact Swift Glass to learn how our cutting-edge solutions can help you stay ahead of the curve in a rapidly evolving market.

Request a Quote for Temporary Tempered Glass Well Plugs