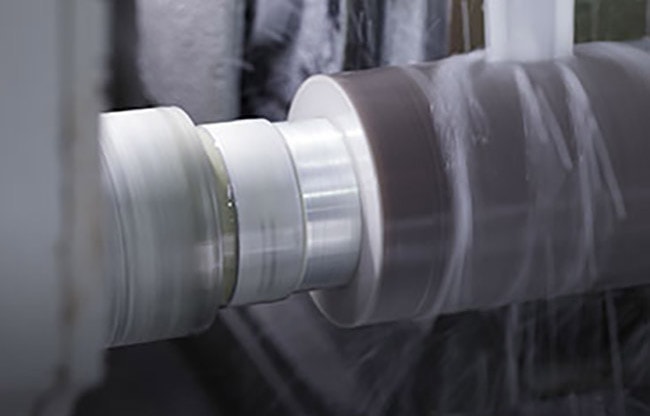

A diamond wire saw uses a hydraulic motor to pull a diamond wire along the surface of a workpiece. The diamond glass beads create friction that can cut any material, from titanium to reinforced concrete to glass. Swift Glass has nearly 100 years of experience in the custom glass cutting and fabrication industry. Our glass-cutting capabilities, experienced technicians, and advanced machinery ensure a precise solution for your custom glass-cutting needs.

Here we will explore diamond wire saw glass cutting, showcasing the benefits and applications and providing an overview of Swift Glass’s equipment and capabilities.

The Benefits of Diamond Wire Sawing for Glass Cutting

Diamond wire saw for glass cutting offers various benefits, including the following:

- Accuracy & Precision: Diamond wire saws offer high precision and accuracy, delivering standard shapes and cuts in glass materials.

- Reduced Material Waste: The accuracy of diamond wire saws reduces kerf loss and minimizes material waste.

- Reduced Chipping: Unlike other cutting tools, diamond wire saws result in minimal chipping and damage to the glass workpiece, eliminating the need for additional polishing processes.

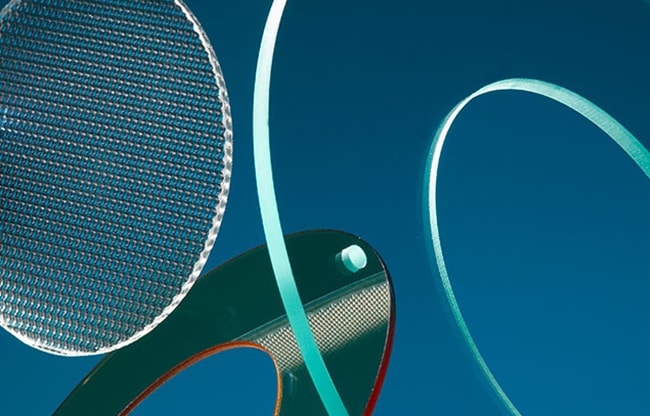

- Versatility: Diamond wire saws can cut glass of various types and thicknesses. They can cut everything from thick glass panels to thin sheets and work with numerous glass compositions.

- Environmental Friendly: In addition to producing less material waste, diamond wire saw cutting consumes less energy than other methods, making it a more sustainable cutting method.

- Customization: Diamond wire saw cutting is ideal for custom glass cutting tasks, allowing the operator to make unique shapes and sizes.

Industries Served

Various industries depend on diamond wire saw cutting for its efficiency and precision, such as the following:

- Solar Panel Manufacturing: Diamond wire saws deliver high-precision cuts to increase yield and minimize waste, making them ideal for cutting glass substrates for solar panels.

- Display and Electronics Industry: Diamond wire sawing delivers accurate and clean cuts in glass for OLED displays, LCD panels, and touchscreen devices.

- Automotive Glass: The automotive industry relies on diamond wire saw cutting to cut glass windshields, sunroofs, and side windows for vehicles. The highly precise process reduces waste and provides accurate dimensions for each vehicle.

- Optical Components: Diamond wire saws are suitable for accurately cutting high-precision optical lenses, mirrors, and prisms. Their precise and clean cuts deliver the necessary optical quality.

- Laboratory Glassware: Laboratories rely on diamond wire saw cutting to cut glassware with smooth edges and accurate dimensions.

- Aerospace Industry: Diamond wire saw cutting is used in producing glass components for spacecraft and aviation, such as instrument panels and cockpit displays.

- Semiconductor Glass Wafer: Diamond wire saw cutting is invaluable to the semiconductor industry, delivering precision cutting for glass wafers.

- Specialty Glass Cutting: Specialty glasses like fused quartz and borosilicate benefit from the precise and intricate cutting capabilities of diamond wire saw cutting. It is used in product development, research, and manufacturing specialty glass products.

Our State-of-The-Art Diamond Wire Saw Equipment

Swift Glass uses state-of-the-art diamond wire saw equipment. Our line of production equipment consists of these machines:

- Multi-Diamond Wire Saw – GTI MWS-812SD: This fast and efficient cutting machine is ideal for mass production of large-scale industrial glass. We rely on our multi-diamond wire saws for automotive, photovoltaic, and semiconductor glass applications. These machines deliver high throughput for quick and efficient production of components up to 8 in. (200 mm) in diameter and 12 in. (300 mm) long.

- Single Diamond Wire Saw – Somos-IWT Model CR500: Our single wire saws are ideal for short-run production applications, such as research and development purposes. These single diamond wire saws are suitable for delivering high precision for delicate glass materials.

Why Work With Swift Glass?

Swift Glass is a custom glass cutting and fabrication leader with nearly a century of experience delivering solutions to the commercial, industrial, appliance, biomedical, aerospace, optical, and other sectors. As an ITAR-registered and ISO 9001:2015 certified manufacturer, we possess advanced machinery for glass cutting and work with leading glass brands, including Corning, Auer, GE, and Schott. Our stock materials include specialty glass like BOROFLOAT®, VYCOR®, and PYREX®, and polished plate glass. We have the equipment and expertise necessary to perform advanced cutting techniques like diamond wire sawing at competitive prices.

Contact Us for All Your Glass Cutting Needs

Diamond wire sawing delivers intricate and precise cuts for glass panels and sheets in various shapes and sizes with high production speeds and minimal waste. Numerous industries depend on diamond wire sawing to cut glass to exact dimensions with clean and smooth edges. Swift Glass uses state-of-the-art multi-diamond and single-diamond wire sawing machines to deliver a glass-cutting solution that meets your needs.

In addition to diamond wire sawing, Swift Glass offers the following capabilities on-site at our New York facility:

- CNC machining

- Ultrasonic machining

- Chemical strengthening

- Bending

- Waterjet cutting

- Drilling

- Thermal tempering

- Edge grinding

- Inkjet printing

- Silk screening and decorating

Learn more about our custom glass-cutting capabilities. To get started with your solution, request a quote or contact Swift Glass today.