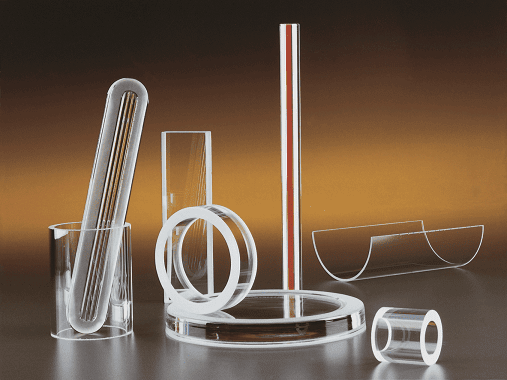

Swift Glass is a worldwide industry leader in manufacturing quality industrial glass components. For nearly 100 years, we have provided our clients with high-quality products and services, helping them with the best glass materials for their specific applications. We offer a full range of capabilities and carry an extensive inventory to meet the demands of industries such as optical, biomedical, aerospace, automotive, and more.

Our glass guide will explain the differences between different types of glass and their respective applications, so you can choose the right option for your project.

Selecting the Best Type of Glass for Your Industrial Needs

Common types of industrial glass include soda lime, borosilicate, fused silica, and high lead glass. When choosing the best type of industrial glass, it is critical to understand each glass material’s chemical, physical, and thermal properties to ensure it can withstand the environment and demands of the specific application.

Factors to consider include:

- Applicable standards

- Corrosion resistance

- Shock resistance

- Thermal expansion

- Refractive index

Download a free copy of our Glass Material Properties Chart to discover these properties and learn which glass material is most suitable for your desired application.

Types of Glass Materials – Glass Composition

Many industrial applications rely on fused silica (also called fused quartz). This material consists of silica in a non-crystalline (amorphous) form. Due to its high melting point and strength compared to ordinary glass, fused silica is an optimal solution for rapid temperature changes and high-temperature environments. Featuring a three-dimensional structure, fused silica offers several advantages:

- Near-zero thermal expansion

- Excellent resistance to thermal shock

- Ultraviolet (UV) transparency

Soda-lime silicate is another popular type of industrial glass, often used in food and beverage glass containers and window panes. While the material can be re-melted for reuse in various applications, it does have poor corrosion, abrasion, and thermal shock resistance.

Laminated soda lime is often inserted between two or more layers of glass to increase their strength and bind the layers. This material and technique is commonly used in the automotive and architectural industries.

Important Glass Properties

At ordinary temperatures, glass material is an exceptional electrical and thermal insulator, a nearly perfect elastic solid, and extremely corrosion-resistant. Most glass properties depend on its atomic structure and chemical composition. The higher the alkali concentration, the lower the electrical resistivity and chemical durability.

Selecting the right glass for a specific application requires an understanding of the material’s different properties, which can include the following:

- Thermal Properties: These properties dictate how well the glass conducts heat away from the light/heat source, which is helpful for applications with exposure to high infrared or high temperatures. Each industrial glass type has a thermal shock rating and maximum operating temperature, and thermal properties can determine the amount of heat the material can withstand and how it cools after rapid temperature changes. Heat tempering, chemical strengthening, and heat strengthening can alter these properties.

- Optical Properties: Optical properties refer to the amount of light passing through the glass. It’s important to know when manufacturing optical devices, such as lenses, as tinted materials will absorb more light.

- Chemical Properties: Extended exposure to vapors, water, or other liquids will cause the glass’s sodium/alkali metal ions to migrate to the glass surface in a process known as alkali leaching, causing a haze. A barrier coating, such as silicon dioxide, can limit the reaction and must be considered especially for high-humidity applications.

- Electrical Properties: When selecting glass for electronic applications, consider its electrical properties, which include volume resistivity, dielectric constant, conductivity, and surface resistivity.

- Mechanical Properties: A glass’s mechanical properties determine the amount of stress the material can withstand. Tensile stress failure causes most breakage.

Industrial Glass Applications

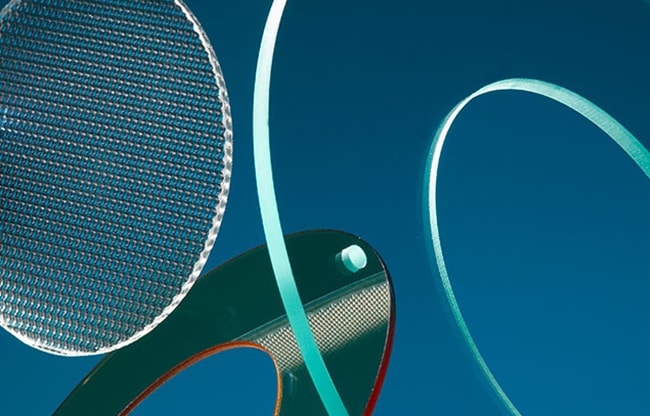

Glass proves beneficial in a vast range of applications and industries, some of which include:

- Aerospace

- Lighting

- Optical

- Medical

- MEMs and Microfluidic Devices

- Military

- Petrochemical

- Photonics

- Pressure Sensors

- Renewable Energy

- Semiconductor

Swift Glass, Your Trusted Custom Glass Manufacturer

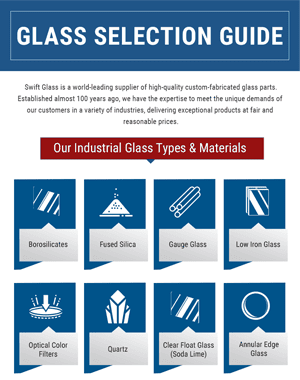

Swift Glass is a world-leading supplier of high-quality custom-fabricated glass parts. Established almost 100 years ago, we have the expertise to meet the unique demands of our customers in a variety of industries, delivering exceptional products at fair and reasonable prices.

Our Industrial Glass Types & Materials

At Swift Glass, we stock materials from a wide variety of glass manufacturers, including Corning, Schott, GE, Vitro, and more. Our Glass Materials Guide helps customers navigate our extensive product selection, identifying which material best matches their performance and physical capability requirements.

Glass Manufacturing Capabilities

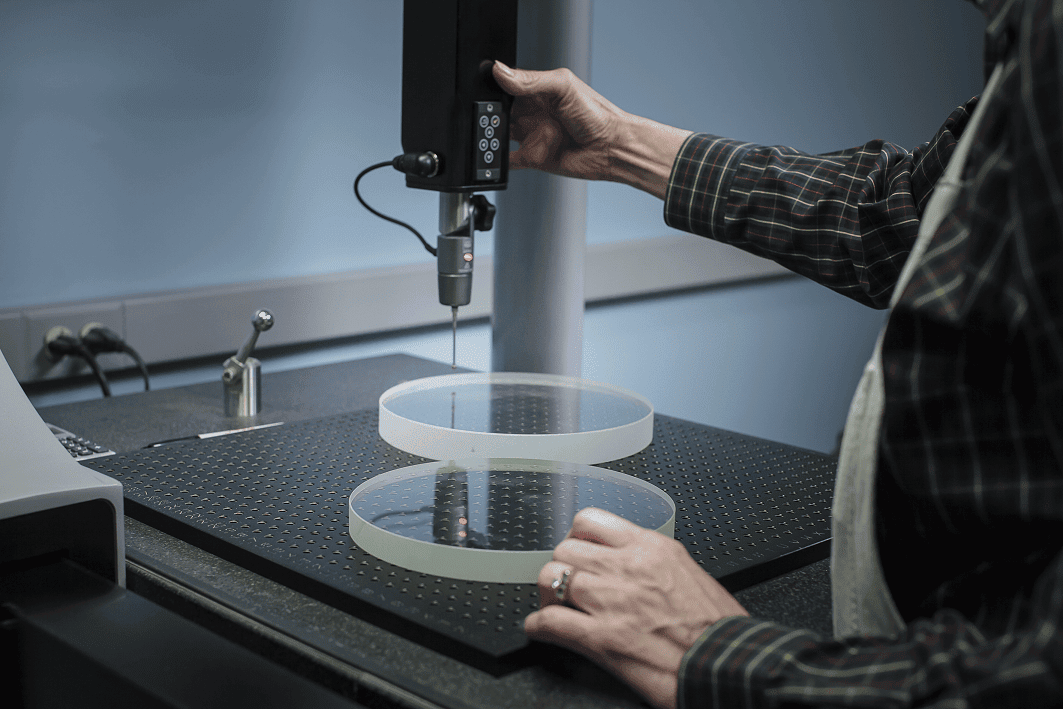

Swift Glass provides premium glass services to meet high industry standards and our clients’ specifications. Just some of our glass fabrication capabilities include:

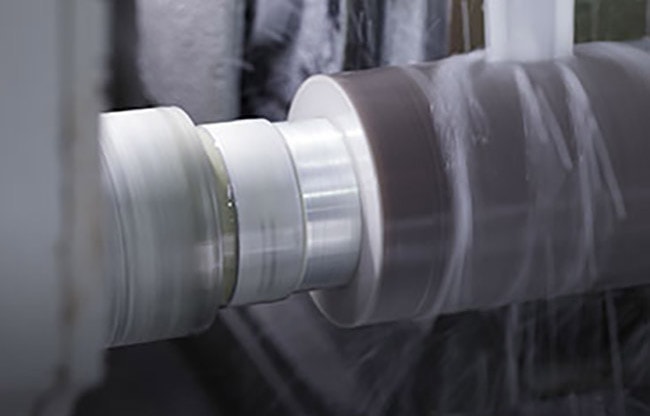

- Glass CNC Machining

- Glass Cutting & Waterjet Cutting

- Edge Grinding & Polishing

- Thermal Glass Tempering & Chemical Glass Strengthening

- Surface Lapping & Polishing

- Glass Wafer Fabrication

- Glass Drilling

Industry Standards & Certifications

Swift Glass has decades of experience working with companies in the military, optical, biomedical, and other industries that demand stringent standards and requirements. We can meet dozens of industry standards to ensure your glass provides superior quality and performance, including:

- MIL-Specs

- ASTM Standards

- International Standards

- ISO 9001:2015 Certification

Contact Our Experts for Premium Glass Fabrication Solutions

At Swift Glass, we have developed a reputation for being a trusted custom industrial glass manufacturer, providing quality solutions for original equipment manufacturers. Our premium glass services and commitment to excellence meet our clients’ specifications and high industry standards.

Contact us today or request a quote to learn more about our extensive selection of glass materials and manufacturing capabilities all under one roof.