The aerospace industry is one of many that rely on high-quality glass materials. Commercial and military applications in the aerospace industry use optical and other equipment to help conduct surveillance and increase the safety of personnel. Along with other material solutions, these applications require display glass and other glass components that can help ensure aircraft reach their destination.

At Swift Glass, we have nearly 100 years of experience fabricating custom glass solutions for the aerospace industry and many others. We maintain ISO 9001:2015, ITAR, MIL-Spec, ANSI, and ASME certifications to ensure our solutions meet the highest industry standards.

Aerospace Applications for Custom Glass Solutions

Glass has many applications in the aerospace industry. Some of these applications include:

- Optics. Aircraft components such as cockpit displays use a variety of glass filters to enhance visual clarity. LCD and analog instruments also use reliable instrument glass to give pilots a clear view of their readings. Other optical glass parts used in the aerospace industry include glass heads-up displays (HUDs), gyroscopes, and more.

- Tempered glass. Flight deck windows often use a thin layer of protective tempered glass, which is bonded to a thicker polymer layer.

- Prism rods. Glass prisms allow for orientation adjustments and ray deviation in various types of equipment. Applications such as spectrographs, telescopes, surveying equipment, and refractometers frequently use glass prisms.

- Coatings. High-silica glass glazes can provide coatings for ceramic tiles, which space shuttles depend on to prevent burning up in the earth’s atmosphere upon reentry. Mirrors, paneling, and LED lighting may also use glass coatings. While we don’t perform coating in-house, we can get glass coated to meet the needs of specific applications.

- Gauges/avionics. In the past, cockpits primarily used steam gauges, but the advantages of glass have led to the implementation of glass gauges and avionics. Glass cockpits generally benefit from more reliability because they use batteries as their sole power source instead of outdated analog technology and vacuum pumps.

- LED lighting. LED lighting systems allow for improved reliability, a longer lifespan, and increased ease of installation. To maintain these systems, aircraft use high-quality glass materials.

- Space vehicle windows. Astronauts need windows in space vehicles to get a clear view of their surroundings and keep them sufficiently protected from exposure to extreme temperatures. In facilitating this, space vehicle windows need highly durable glass that provides thermal stability and thermal shock resistance.

Is Your Glass Material Suitable for Your Application?

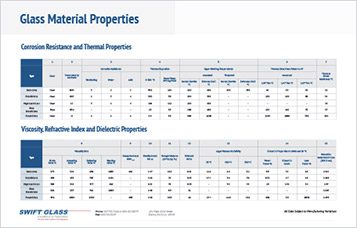

Find out with our Glass Material Properties chart.

Understanding your glass material’s thermal, chemical and physical properties is critical to ensure it can withstand the application’s use and environment.

Materials

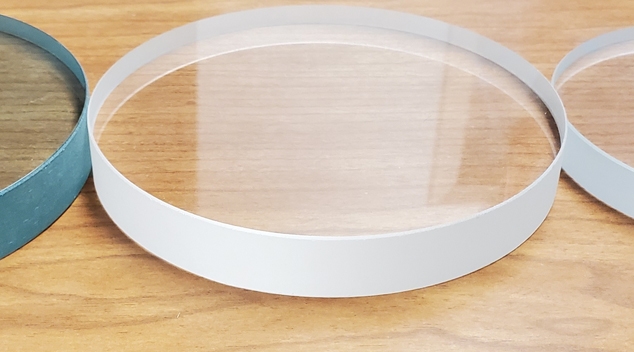

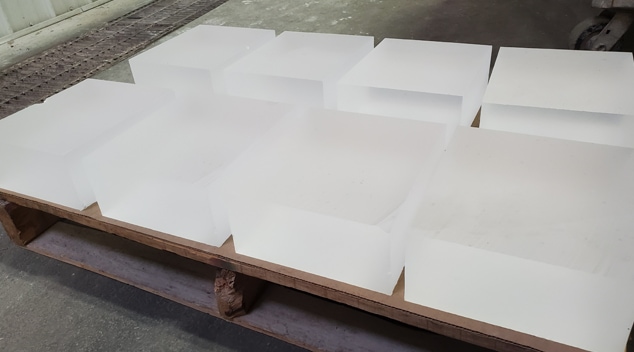

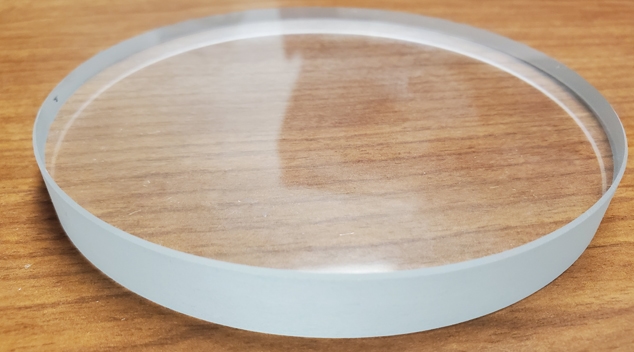

Depending on our customers’ individual requirements, Swift Glass offers a broad array of glass material options, including:

- Borosilicate

- Clear soda lime float glass

- Corning® Gorilla® Glass

- Fused silica

- Gauge glass

- Glass rods/tubing

- Low iron glass

- Optical color filters from Hoya, Kopp, and SCHOTT

- Quartz

- SCHOTT Supremax 33®

- Starphire

- Vycor® alternatives

- Custom glass solutions

Quality Aerospace Glass Fabrication from Swift Glass

At Swift Glass, we have an ongoing commitment to creating a safe working environment and providing exceptional quality. To ensure optimal quality, we are ISO 9001:2015-certified, ITAR-registered, and utilize the following equipment:

- A clean room

- Ultrasonic bath system

- A dark room

- An optical comparator

- Optical flats

- Spectrophotometer

- And other pertinent inspection equipment

Swift Glass has grown into a market leader in fabricated glass parts and custom glass solutions, and we continue to provide our customers with top-quality glass products. To see how our custom glass fabrication capabilities can benefit your aerospace application, contact us or request a quote today.