Pressure sensors monitor for pressure within a system and, when sensors recognize air, gas, or liquid pressure, they effectively translate that information into an electrical signal for use in an application.

A pressure-sensitive component couples with a signal processor to generate a response in the system. Many applications use pressure sensors to maintain pressure and obtain precise pressure readings, including various components in vehicles, consumer electronics, and healthcare devices. They are also preferred parts for industrial construction applications.

Glass is particularly well suited for pressure sensor composition because of its strength, chemical and thermal resistance, and electrical insulation, all while providing optical transparency. At Swift Glass, we utilize ultrasonic machining and glass wafers to provide high-quality glass pressure sensor fabrication services.

How Do Glass Pressure Sensors Work?

Glass pressure sensors use a couple of core components to convert pressure into an electrical signal that applications can use. The main component of a glass pressure sensor is a micro-electromechanical systems (MEMS) die, which serves as the pressure-sensing element. The MEMS component will bend when under pressure. Piezoresistors monitor for that motion and, in its presence, alter it into a form of electrical signaling. An application-specific integrated circuit (ASIC) within the system examines the amount of generated electrical charge to determine the pressure’s strength, and can then utilize that information within the system for pressure management.

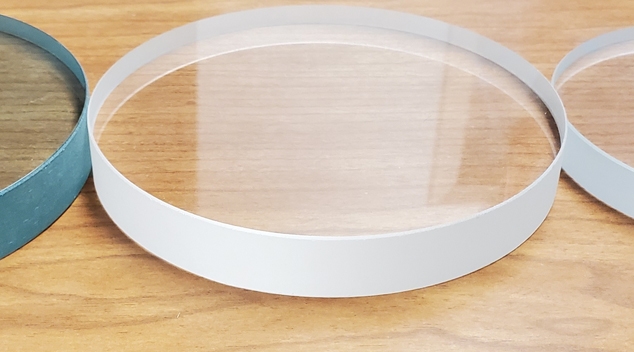

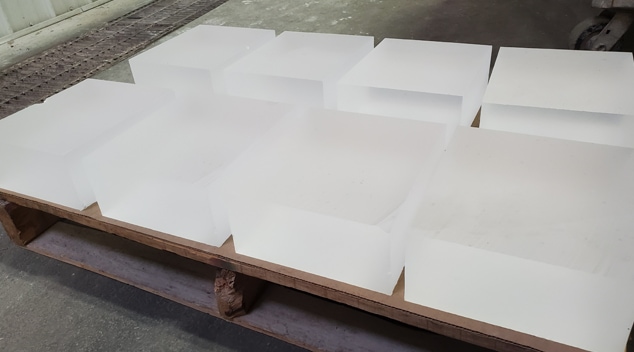

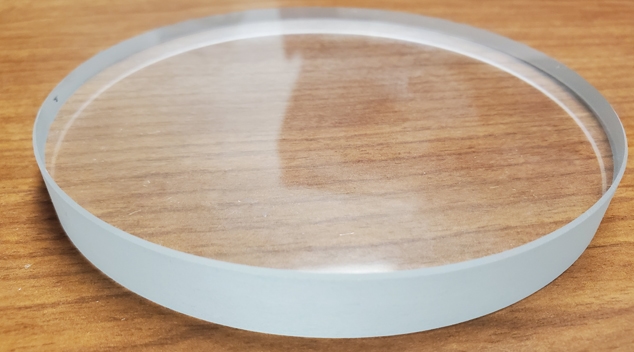

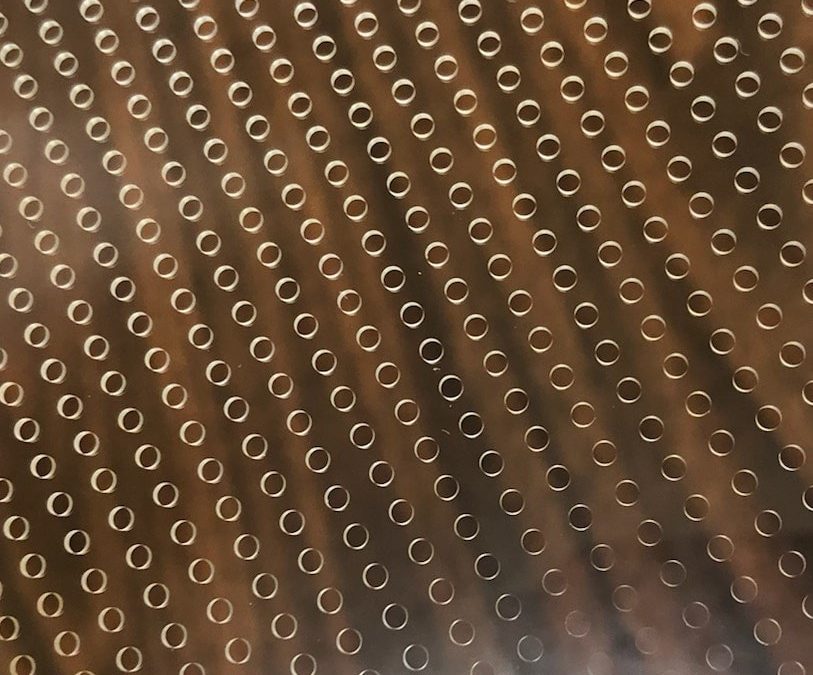

The MEMS component rests on a surface within the sensor that acts as a through-hole, which directs pressure to the component’s membrane. In glass pressure sensors, glass wafers of materials like Borofloat®, fused silica, and quartz are ideal for this application. Depending on the sensor application, pressure sensors will need to meet certain requirements around thickness, flatness, and the size of the through-hole. For example, durable and corrosion-resistant Borofloat® is ideal for sensors that require flatness, while MEMS work well to form thin pressure sensors.

Advantages of Glass Wafers for the Pressure Sensor Industry

Glass wafers are important components for pressure sensor fabrication. Beyond their mechanical strength, these wafers offer a number of benefits to pressure sensor applications, such as:

- Stability due to low electrical conductivity

- Precision

- Flexibility and versatility of shapes

- Corrosion and heat resistance

For any necessary processing, ultrasonic machining is an ideal technique for glass wafers.

Ultrasonic Machining Capabilities at Swift Glass

For over a century, Swift Glass has served as a glass fabrication leader for OEM and specialty applications. Our list of services includes everything from traditional cutting and grinding to laser cutting and ultrasonic machining, or ultrasonic drilling.

This subtractive machining technique uses a combination of ultrasonic vibrations and abrasive particle slurry to drill into glass, creating shapes and holes with the progressive removal of minute amounts of surface material through abrasion. Through ultrasonic machining, we can fabricate a wide range of parts, including glass pressure sensors. This process is particularly ideal for glass components because of its ability to accurately and finely grind material on the component’s surface without negatively impacting the part.

Ultrasonic machining does not need heat, chemicals, or electricity to process the glass, which further minimizes the stress these parts experience. As a result, this process creates consistently high-quality components that work in a wide variety of operational conditions. After suspending abrasive particles in liquid to form the abrasive slurry, machine-targeted energy waves then cause the slurry to vibrate and work against the glass’s surface and shear off small amounts of surface material until forming the intended hole or shape. A highly accurate and precise process, it generates reliable drilling depth. Following this procedure, glass parts undergo finishing treatments such as grinding and polishing to meet all final specs.

Contact Swift Glass

At Swift Glass, we provide high-quality ultrasonic machining services for precision drilling in glass wafers and other glass parts. Using state-of-the-art equipment, our team will not only meet your expectations, but also ASME, ASTM, and MIL-SPEC standards to best serve our customers.

If you would like to find out more about our ultrasonic machining capabilities for pressure sensors and other components, contact us today or request a quote to get started.