How to Select High Performance Glass

High performance glass is in demand for a variety of applications that require durable and reliable glass products, including windows for industrial and safety applications that must withstand bullets, explosions, and high pressure. In addition to windows, high performance glass is useful for industrial lighting products, military, medical and many other applications.

High Performance Glass Stress Points

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass, high performance, or tempered, glass breaks into small pebble-shaped pieces that are less likely to cause severe injury.

The value of high performance glass comes from its high breaking point and the manner in which it breaks. Rather than shattering into long, sharp pieces like standard annealed glass, high performance, or tempered, glass breaks into small pebble-shaped pieces that are less likely to cause severe injury.

High performance glass is used particularly in situations where certain external forces would break untreated glass, as it can withstand stress more easily. It is especially useful in applications where the following factors may be encountered:

High Pressure

High pressure from architectural stress, water pressure from marine environments, or extreme pressure variations in aerospace applications can cause breakage and damage of standard annealed glass. High performance tempered glass provides an excellent alternative to ensure both durability and safety in environments where extreme pressure changes are common.

Intense Temperatures

In certain industrial environments, tempered glass is an excellent material for windows and other glass components, as it is highly resistant to temperature changes and has a higher resistance to thermal shock.

Harsh, Wet, and Extreme Environments

Heat strengthened glass is useful in applications with exposure to harsh weather conditions. With its thermal resistance and tensile strength, high performance glass is an ideal material for high winds, rain, and temperature extremes.

Explosions, Bullets, and Projectiles

Tempered glass is frequently used in the production of car windshields, industrial windows, and other applications where its impact-resistant nature is useful. In the event that tempered glass does break, it is into small pieces that are much less dangerous than typical sharp shards produced by standard glass.

The Thermal Glass Tempering Process

What Is Tempered Glass?

What Is Tempered Glass?

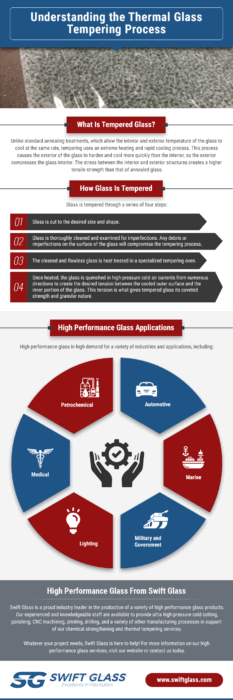

Unlike standard annealing treatments, which allow the interior and exterior temperature of the glass to cool at the same rate, tempering uses an extreme heating and rapid cooling process. This process causes the exterior of the glass to harden and cool more quickly than the interior, so the exterior compresses the glass interior. The stress between the interior and exterior structures creates a higher tensile strength than that of annealed glass.

Tempered glass is also more heat resistant, and can withstand heat up to 470°F, which could cause untreated glass to shatter or crack. The main benefit of tempering is the compression prevents the glass from breaking into jagged pieces upon impact. Rather, the glass crumbles into less dangerous rounded pebbles.

How Glass Is Tempered

Glass is tempered through a series of four steps:

- Glass is cut to the desired size and shape.

- Glass is thoroughly cleaned and examined for imperfections. Any debris or imperfections on the surface of the glass will compromise the tempering process.

- The cleaned and flawless glass is heat treated in a specialized tempering oven.

- Once heated, the glass is quenched in high-pressure cold air currents from numerous directions to create the desired tension between the cooled outer surface and the inner portion of the glass. This tension is what gives tempered glass its coveted strength and granular nature.

High Performance Glass Applications

High performance glass in high demand for a variety of industries and applications, including:

- Automotive

- Marine

- Military and Government

- Lighting

- Medical

- Petrochemical

High Performance Glass From Swift Glass

Swift Glass is a proud industry leader in the production of a variety of high performance glass products. Our experienced and knowledgeable staff are available to provide ultra high-pressure cold cutting, polishing, CNC machining, printing, drilling, and a variety of other manufacturing processes in support of our chemical strengthening and thermal tempering services.

Whatever your project needs, Swift Glass is here to help! For more information on our high performance glass services, visit our website or contact us today.