Companies that rely on precision glass components need a partner that can deliver speed, accuracy, and consistent quality. With nearly 100 years of experience in advanced glass fabrication, Swift Glass provides laser glass cutting services for industries where clean edges, intricate designs, and tight tolerances are critical.

Our advanced glass laser cutting capabilities allow us to produce complex parts with micron-level accuracy while minimizing defects. Whether you need prototypes or high-volume production, Swift Glass is equipped to handle your project efficiently.

Why Choose Laser Glass Cutting at Swift Glass

Customers across aerospace, medical, optical, petrochemical, and other critical industries turn to Swift Glass for reliable laser glass processing. Our advantages include:

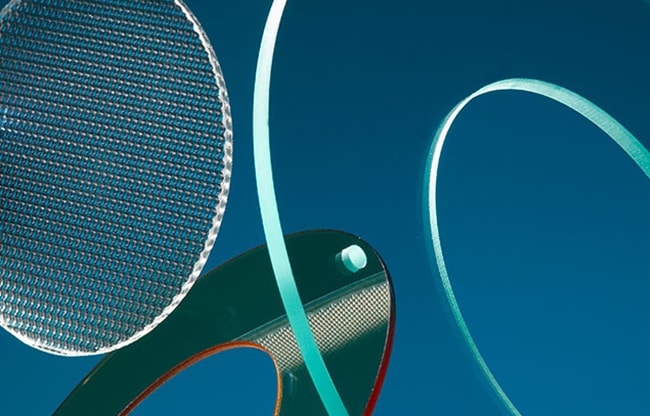

Materials We Laser Cut

Swift Glass works with a wide range of glass and exotic substrates. Examples include:

- Soda-lime glass

- Borosilicate (including Borofloat®)

- Quartz and fused silica

- Sapphire (specialty exotic material)

- Patterned and specialty-coated glass

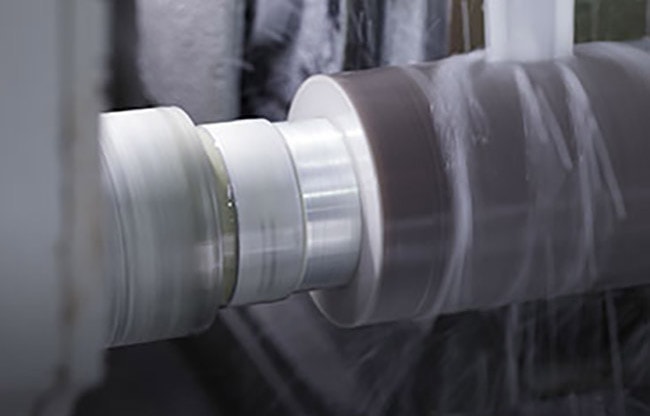

Laser Glass Cutting Capabilities

Our advanced photonics glass cutting equipment is capable of drilling holes in glass substrates with minimal taper and variable drilling speeds. Key parameters include:

- Drillable Hole Sizes: 50 µm to 50 mm in a single operation

- Maximum Feature Size: 300 mm x 300 mm (in 50mm sections)

- Substrate Thickness: 50 µm to 10 mm

- Drilling Speeds: Over 30mm/sec in 0.5mm glass

- Other Capabilities: Scribing and marking at speeds up to 2000mm/sec

Industries and Applications of Laser-Cut Glass

We provide custom laser cut glass solutions for industries where precision and reliability are essential, including:

- Semiconductor

- Medical

- Automotive

- Optoelectronics

- Aerospace

- Flat Panel Displays

Swift Glass: Your One-Stop Shop for Precision Glass Solutions

Swift Glass is more than a glass laser cutting provider; we offer a full suite of glass fabrication capabilities, including edge grinding and polishing, thermal glass tempering, chemical glass strengthening, microblast machining, and more. This allows us to complete your project from start to finish, ensuring quality at every stage.

With nearly 100 years of expertise, ISO certification, and a commitment to customer success, Swift Glass is a trusted partner for industries worldwide. Contact us or request a quote today to get started.