Fused silica is a versatile material used in industrial glass fabrication. Because of its unique properties, it can be used to create a wide range of glass products used in diverse industries around the world. Learn more about what fused silica is, its characteristics and benefits, and popular applications of the material. Also, see how Swift Glass can fabricate fused silica glass products for your next industrial project.

What Is Fused Silica?

Fused silica is a processed form of silicon dioxide that has a noncrystalline structure. Also called synthetic fused silica, this material can be made through:

- Using gas or electric heat to melt silica grains into a single form, or

- Using chemicals to synthesize the glass

Either process creates a cohesive, cross-linked 3D structure that offers excellent optical characteristics, has resistance to thermal shock, and offers a low thermal expansion coefficient, meaning it won’t significantly expand as the temperature increases.

Fused Silica Properties

Fused silica offers several beneficial properties that make it an ideal material to use in glass fabrication of optical products, high-tech goods, and various other applications. These include:

-

Chemical Properties

Fused silica creates a chemically inert glass, and it's considered to have a high level of chemical purity. This means it can be exposed to several different types of chemicals used in commercial, industrial, and laboratory settings without degradation or suffering damage. While it can be damaged by both potassium hydroxide and hydrofluoric, it's compatible with most other chemicals.

Chemical Properties

Fused silica creates a chemically inert glass, and it's considered to have a high level of chemical purity. This means it can be exposed to several different types of chemicals used in commercial, industrial, and laboratory settings without degradation or suffering damage. While it can be damaged by both potassium hydroxide and hydrofluoric, it's compatible with most other chemicals. -

Electrical Properties

Fused silica glass is electrically insulative. Its electrical resistance changes based on its temperature, ranging from 1018 Ω*cm (20 °C) to 1010 Ω*cm (400 °C). It also offers good dielectric properties and high-frequency properties, with a low dielectric constant and low dielectric loss. Because the silicon-oxygen bonds in the material's structure have large gaps, only the ionic impurities in the material can carry current and conduct electricity, making it extremely resistant.

Electrical Properties

Fused silica glass is electrically insulative. Its electrical resistance changes based on its temperature, ranging from 1018 Ω*cm (20 °C) to 1010 Ω*cm (400 °C). It also offers good dielectric properties and high-frequency properties, with a low dielectric constant and low dielectric loss. Because the silicon-oxygen bonds in the material's structure have large gaps, only the ionic impurities in the material can carry current and conduct electricity, making it extremely resistant. -

Mechanical Properties

One of the most unique — and most advantageous — properties of fused silica is its elasticity. Fabricators can create flexible micro-mechanical components that would otherwise face breakage or wear during motion. While standard glass can't be used to produce flexible microdevices because it poses a risk for developing cracks during finishing stages, fused silica is much more resilient and resistant to microcracking. Fused silica can also be incredibly strong and resistant to compression; damage is more likely to occur due to tension than compression.

Mechanical Properties

One of the most unique — and most advantageous — properties of fused silica is its elasticity. Fabricators can create flexible micro-mechanical components that would otherwise face breakage or wear during motion. While standard glass can't be used to produce flexible microdevices because it poses a risk for developing cracks during finishing stages, fused silica is much more resilient and resistant to microcracking. Fused silica can also be incredibly strong and resistant to compression; damage is more likely to occur due to tension than compression. -

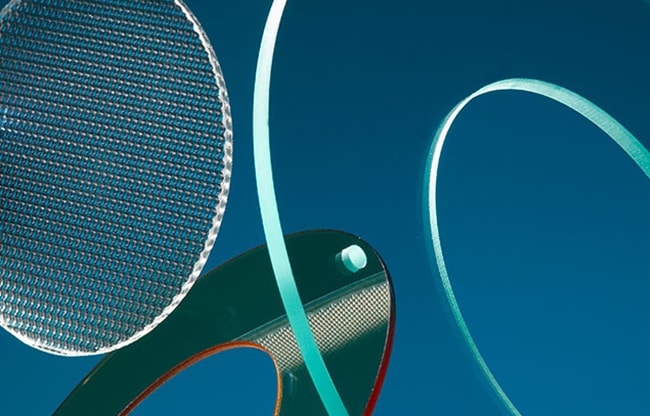

Optical Properties

Fused silica is a highly transparent material that can be used for applications with light ranging from ultraviolet light to infrared light, covering the entire spectrum of visible light and stretching far beyond it. Fabricators can also customize parts' transmission by modifying the techniques used during production and the level of purity. Contaminants such as aluminum, iron, and sodium can alter optical absorption.

Optical Properties

Fused silica is a highly transparent material that can be used for applications with light ranging from ultraviolet light to infrared light, covering the entire spectrum of visible light and stretching far beyond it. Fabricators can also customize parts' transmission by modifying the techniques used during production and the level of purity. Contaminants such as aluminum, iron, and sodium can alter optical absorption. -

Thermal Properties

Fused silica has a low and very consistent coefficient of thermal expansion, making it an excellent choice of material for components that need to remain stable throughout exposure to a wide range of temperatures. This characteristic, along with its excellent dimensional stability, gives it the ability to withstand thermal shock and any associated damage.

Thermal Properties

Fused silica has a low and very consistent coefficient of thermal expansion, making it an excellent choice of material for components that need to remain stable throughout exposure to a wide range of temperatures. This characteristic, along with its excellent dimensional stability, gives it the ability to withstand thermal shock and any associated damage.

Quartz vs. Fused Silica

Quartz is another substance that’s popularly used in glass fabrications. Quartz is also an amorphous and noncrystalline product that offers good electrical, optical, and thermal characteristics; however, quartz features key differences in terms of structures and creation.

Key properties of quartz include:

- Features a low OH content

- Crafted from naturally occurring crystalline quartz or silica grains

- Retains some residual impurities from raw material, which affects ultraviolet transparency

While these materials are often interchangeable, fused silica has the highest temperature characteristics of any glass and superior ultraviolet performance compared to natural quartz. Key features of fused silica include:

- Cross-linked 3D structure

- Significant transparency into deep ultraviolet

- Retains some residual impurities from water vapor in processing, which affects infrared transparency

Distinctive features that these materials share include exceptional optical transmission, extremely high temperature resistance, and extremely low coefficient of expansion.

Applications for Fused Silica

Because of fused silica’s highly advantageous properties, it can be used in a wide range of precision fabrications for commercial, industrial, and laboratory applications. Some of the most common applications include:

- Chemical and Pharmaceutical Operations. Fused silica parts can withstand exposure to chemicals and pharmaceutical formulas because they're chemically pure and resistant to chemical and thermal damage.

- Electronics/Electro-technology. Fused silica can be used to fabricate insulative parts because they don't conduct electricity, offer high penetration field strength, and ensure low electrical loss.

- High-Temperature Operations. Because fused silica has a low thermal expansion coefficient, it can be used to create parts for high-temperature applications.

- Light and Laser Technology. Fused silica parts can be used in lasers to separate light.

- Optical System Components. Fabricators can produce transmitting optical parts, mirrors, metrology components, and lenses for optical systems.

- Semiconductors. Fused silica is commonly used in semiconductor components due to its purity.

UV Light Sanitation. Fused silica is resistant to high temperatures and radiation, so it can be used to create UV light sanitation equipment. It also allows the passage of UVC light, therefore facilitating disinfection.

Fused Silica Glass Varieties at Swift Glass

At Swift Glass, we specialize in fabricating high-quality fused silica parts for use in optical applications and more. Our fused silica products include industrial fused silica and UV Grade fused silica. Examples of the different fused silica varieties we offer include:

- CORNING® HPFS® 7980 Industrial Grade. This high-purity non-crystalline silica glass offers a low refractive index, excellent optical characteristics, optimal transmittance, and an extremely low thermal expansion coefficient.

- CORNING® HPFS® 7980 UV Grade. This material offers exceptional resistance to thermal shock, near-zero thermal expansion, and UV transparency. It is ideal for low content of inclusions and high refractive index homogeneity.

Learn More About Fused Silica

Fused silica offers a wide range of beneficial properties that make it the ideal material for various optical, chemical, electrical, and high-tech applications. At Swift Glass, we supply fused silica materials to suit the needs of various industries. Contact us to learn more about our fused silica products and fabrication capabilities, or request a quote to start your order.