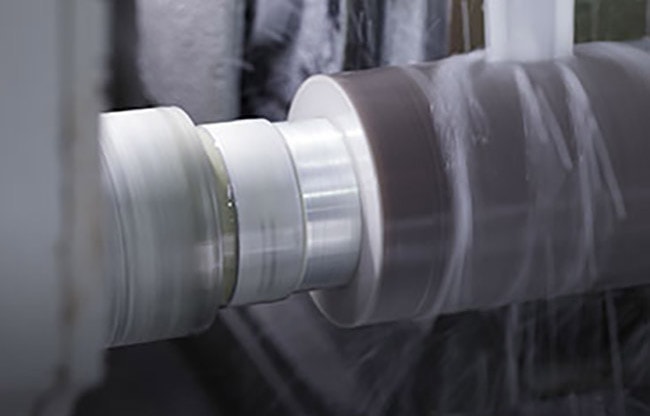

Glass-ceramic materials result from a unique manufacturing process that uses careful temperature management to create a special crystallized structure with properties similar to both glass and ceramic. These materials have a near-zero coefficient of thermal expansion, stability at high temperatures, and excellent resistance to thermal shock and chemicals.

At Swift Glass, we provide SCHOTT NEXTREMA® glass-ceramic material for industrial, manufacturing, and other harsh condition applications. It is available in transparent, translucent, and opaque options, in different sizes and thicknesses, and it has excellent machinability for numerous custom solutions.

Learn more about the benefits of NEXTREMA® and its many uses.

NEXTREMA® Glass-Ceramic Main Material Properties & Benefits

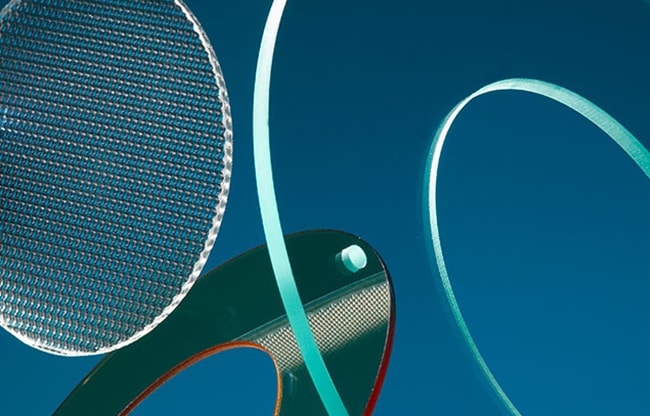

SCHOTT NEXTREMA® glass-ceramic has thermal stability and strength to perform in extreme environments and challenging operating conditions. Key properties include:

- High thermal shock resistance, up to 820°C 1

- Virtually zero thermal expansion

- Good infrared transmission

- Withstands operating temperatures up to 950°C 2

- High mechanical strength and stability, even at high temperatures

- Superior chemical resistance

- Impermeable to gas

- Process inert in most situations

1 Applies to NEXTREMA® transparent. Tested by quenching a homogeneous heated NEXTREMA® transparent panel (820°C) with room temperature water (20°C). Values may differ for other NEXTREMA® variants.

2 Applies to NEXTREMA® opaque white for 1 hour at 950°C homogenous heating. For inhomogeneous heating and other NEXTREMA® variants, the operating temperature may vary.

Additional SCHOTT NEXTREMA® Material Specifications:

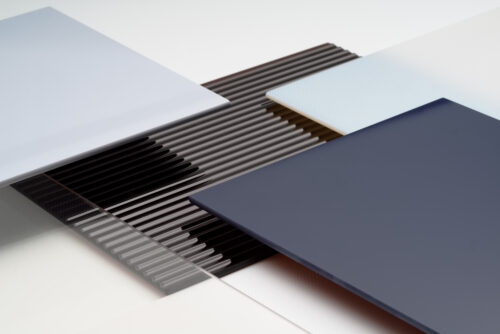

NEXTREMA® is available in several types, sizes, and thicknesses, as follows:

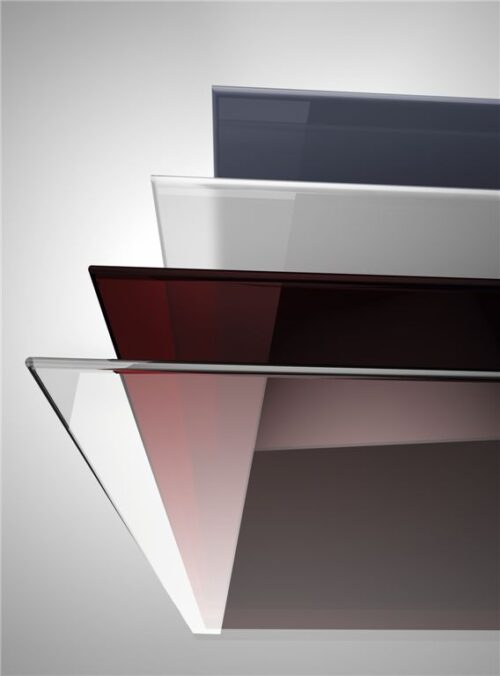

Six types:

- Transparent

- Translucent white

- Opaque white

- Tinted

- Translucent bluegrey

- Opaque grey

Sheet sizes:

- 1600 mm or 1954 mm long

- 900 mm or 1100 mm wide

Thicknesses from 2 mm to 6 mm

Industrial Applications for SCHOTT NEXTREMA® Glass-Ceramics

SCHOTT NEXTREMA® glass-ceramic stands out for its high performance in extreme conditions. It is a durable and reliable material for applications that require high mechanical strength, resistance to thermal shock and chemical exposure, and high operating temperatures. It is used in many industries including:

- Automotive manufacturing

- Food processing

- Solar panel manufacturing

- Display manufacturing

NEXTREMA® is suitable for these and many other applications:

- Industrial soldering and paint drying

- Sealing materials in high-temperature environments, including electrolyzer cells and solid oxide fuel cells

- Industrial furnace viewing windows and insulation material

- Infrared heating elements for grills and spas

- Soldering applications

- CFRP manufacturing

- Sputtering and coating

- Facade cladding

- Outdoor heating

- Commercial ovens

- Heat insulators

Elevate Your Project with SCHOTT NEXTREMA®: Contact Swift Glass Today

SCHOTT NEXTREMA® glass-ceramic material provides superior performance in harsh and high-temperature conditions, and can be custom fabricated to meet your needs. At Swift Glass, we have over 100 years of experience with specialized glass materials. We design and fabricate glass components, including those constructed with NEXTREMA®, to comply with industry standards, including MIL-Spec, ASTM, and international standards. Our facilities are ITAR registered and ISO 9001:2015 certified for quality management.

Contact us to learn more about our glass and glass-ceramic fabrication capabilities, or request a quote to discuss your next project.