Micro-Electromechanical Systems (MEMS) rely on the combined principles of mechanical engineering and microelectronics. MEMS is a growing method of manufacturing miniature chip-based systems and devices, including sensors, actuators, and communication devices. The systems and devices are engineered on a microscale and have dimensions as small as a few micrometers up to a few millimeters. They can consist of microscale mechanical components like channels, membranes, springs, combs, and levers working alongside microscale electrical parts, including inductors, capacitors, and resistors. Various applications, including consumer electronics, medical, aerospace, and automotive devices, rely on MEMS.

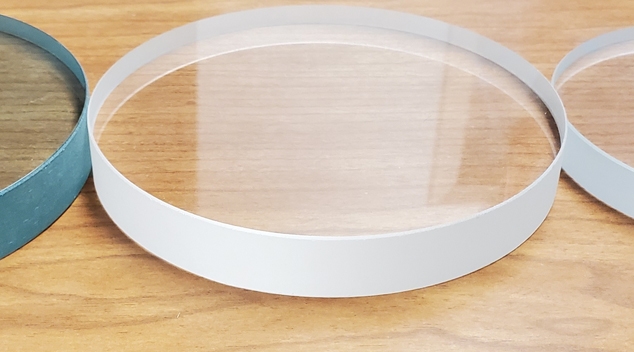

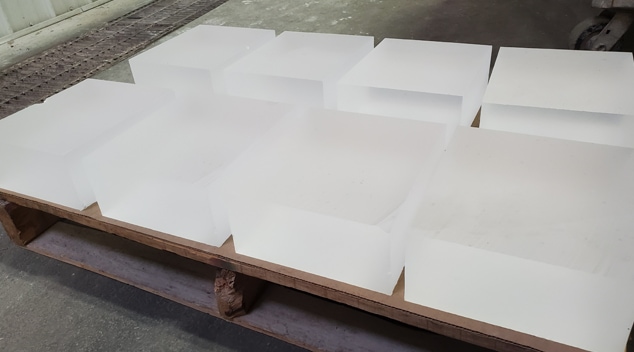

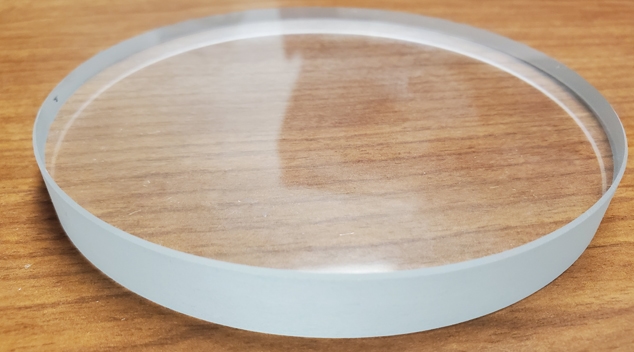

Swift Glass is a custom glass fabricator with nearly 100 years of experience serving various industries with custom glass products. We use high-quality materials from brands like Corning, Schott and GE and a range of in-house machining and fabrication capabilities. Microfluidic devices and MEMS are fabricated using sophisticated technologies. Understanding the fabrication process and the applications that depend on MEMS technology will help you determine if microfluidic devices and MEMS from Swift Glass are ideal for your application.

Applications of MEMS

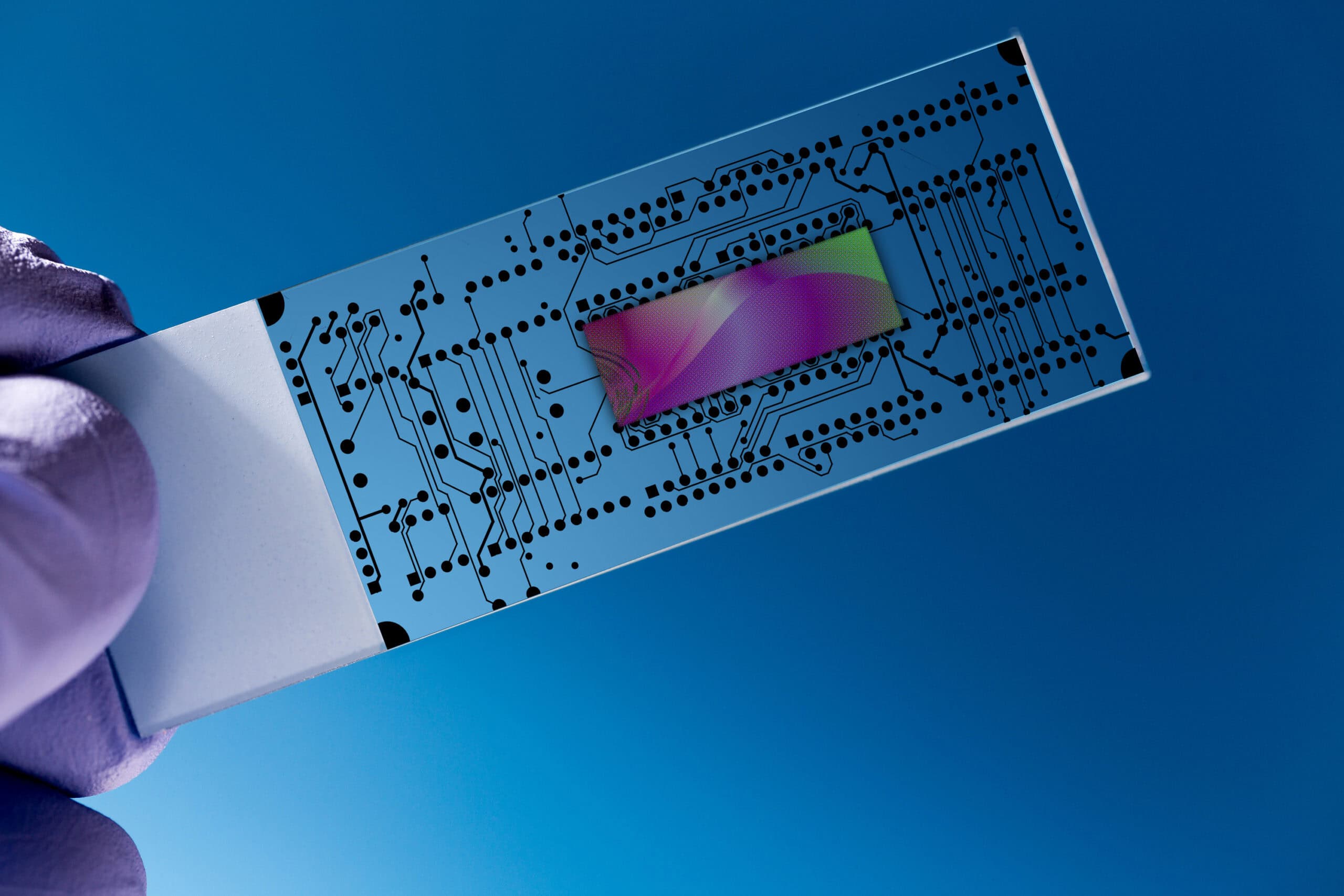

Microfluidic devices heavily rely on MEMS technology. Microfluidic devices allow efficient and precise microscale control and manipulation processes to interact with minuscule amounts of fluids, typically ranging from one attoliter to a few nanoliters. Biological and chemical applications rely on microfluidic devices to automate therapeutic and diagnostic operations, such as medication dispensing. Various other applications depend on microfluidic devices engineered with MEMS technology, including lab-on-chip, environmental monitoring, and drug delivery systems.

MEMS are used in the medical industry, consumer electronics, telecommunications, aerospace, and defense. They are relied on for everything from measuring vacuum pressure during eye surgery to sensing rotation and movement in smartphone accelerometers.

Methods of Microfluidic Device Fabrication

Microfluidic devices can be fabricated using lithography and non-lithography-based methods. Lithography-based methods include:

- Electron beam lithography: A technique that barrages a photomask with electrons to create the desired pattern on a substrate.

- Photolithography: A method that relies on light to create the desired pattern on a substrate using a photomask.

Non-lithography-based methods that do not rely on a photomask are preferred for their simplicity when fabricating microfluidic devices. They include the following non-lithography-based methods.

- Microfabrication by self-assembly: A fabrication method that relies on repulsive and attractive forces applied between the components to spontaneously assemble the parts in a desired configuration.

- Microfluidic molding: A technique that creates microfluidic channels on the substrate using a mold.

- Soft lithography: A fabrication technique that relies on a template or mold to transfer the pattern to the substrate.

The versatility and accessibility of non-lithography-based methods make them popular for fabricating microfluidic devices.

MEMS and Fluidics by Swift Glass

Various applications rely on microfluidic devices and MEMS technology in several industries. Technologies like MEMS and microfluidic devices have developed from advancing fabrication methods. Microfluidic and MEMS technology is expected to be essential to various future applications and industries. Download our Glass Fabrication for MEMS Applications eBook to learn more about the technology behind MEMS and the applications that depend on it.

Swift Glass has delivered custom glass fabrication for nearly a century. We maintain an ISO 9001:2015 certification and ITAR registration to deliver the highest quality glass fabrication services to a worldwide market. Our on-site manufacturing capabilities include waterjet cutting, chemical strengthening, CNC machining, and more. We have worked with leaders in the aerospace, optical, industrial, commercial, appliance, and biomedical fields, delivering innovative solutions. Contact us to speak with a team member about our products and capabilities.