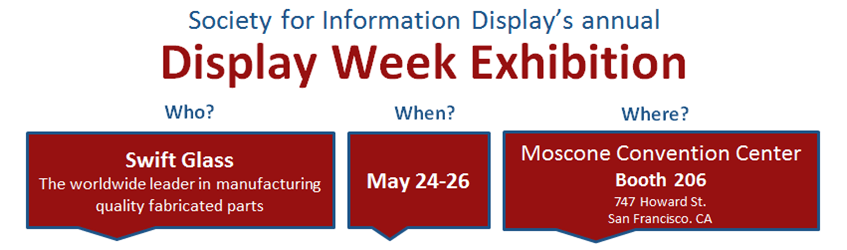

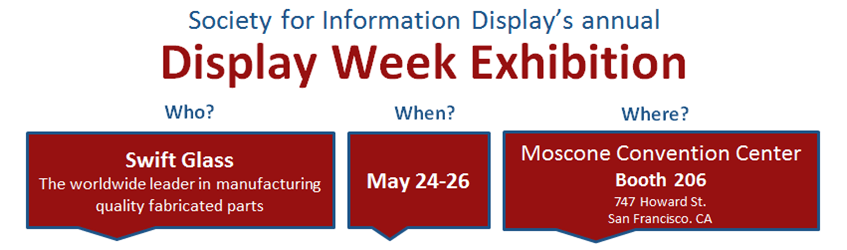

Swift Glass is set to exhibit at the Society for Information Display’s annual Display Week Exhibition from May 24 to 26. The exhibition, held in San Francisco, Calif., brings together companies from around the world to discuss and showcase the latest developments in display technology.

This year’s Display Week will feature nearly 250 exhibitors in display electronics, components, systems, services, manufacturing equipment and other industries. Attendees can expect new innovations to emerge in electronic information display applications — now a $100 billion/year industry.

Swift Glass will join 3M, PPG Industries, Mitsubishi Electric, and other major players in display electronics to showcase our flat glass components and glass capabilities for displays. These include:

• Chemical strengthening for dimensions up to 30” x 40”

• CNC machining

• Heat tempering

• Edge grinding and polishing

• Double-sided lapping and polishing

• Digital screen printing

• Laser etching

Join us at Booth 206 to see our large, chemically strengthened glass parts used for display purposes, and talk to members of our team about your next project.

Can’t attend Display Week? Visit our Optical and Display Glass page for information about our capabilities, and contact us to see how we can help you.

LED lights and lighting systems are becoming increasingly common in the lighting industry.

The rise in the use of LED lights by commercial building owners and managers, and industrial manufacturers is due in part to the federal government’s energy efficiency standards. Updated periodically by the Department of Energy, new efficiency standards in 2012 require lights to use 25% less energy.

More importantly, commercial and manufacturing spaces are also realizing that using LED lighting carries a great number of benefits.

The Benefits of LED

LEDs, or light-emitting diodes, use a semiconductor as a light source. In short, voltage applied to the semiconductor prompts electrons to jump from one atom into an electron hole, an atom with a missing electron. This recombination releases energy in the form of visible light photons.

LEDs, or light-emitting diodes, use a semiconductor as a light source. In short, voltage applied to the semiconductor prompts electrons to jump from one atom into an electron hole, an atom with a missing electron. This recombination releases energy in the form of visible light photons.

The primary benefit of LED lights is their incredible energy efficiency, using as much as 90% less power than standard bulbs. LED bulbs have vastly greater lifespans than standard bulbs, lasting up to 40 times longer — an average of 50,000 hours as compared to about 1,500 hours for incandescent bulbs.

Related to lifespan is their increased durability — the diode is encased in epoxy resin, making it much sturdier than the thin filaments of incandescent lights. They are resistant to shocks, impacts, and vibrations, so they are much harder to break. Their durability also allows for their use in extremely cold and extremely hot applications.

Popular Applications and Installations

LED lighting and lighting systems are being used in a variety of applications. Household use is increasing, as is commercial and industrial usage. But there are other interesting usages arising, as well.

LED lighting and lighting systems are being used in a variety of applications. Household use is increasing, as is commercial and industrial usage. But there are other interesting usages arising, as well.

One of these is in sports arenas. It was long believed to be impossible to light large venues with LED lights, but that has proven to be very false — in 2015, roughly 90% of all large-scale sporting venue operators that installed new lighting systems opted for LED lighting systems. Sports teams across the nation have saved millions of dollars in electricity costs after making the switch.

Another unexpected application for LED lighting has been museums. The University of Oxford’s Pitt Rivers Museum, as an example, switched to LED lighting as part of an effort to reduce its carbon footprint. They’re expected to eliminate 44 tons of carbon from their footprint, not to mention their expected savings up to $64,000, over the next 5 years. As an added bonus, LED lights generate no ultraviolet light at all, protecting the museum’s delicate artifacts from UV damage.

Manufacturing Glass for LED Lighting

Having been manufacturing glass for the lighting industry for more than 80 years, Swift Glass is a nationally recognized expert in lighting glass — including LED lighting glass. We’ve manufactured glass for major LED installers using specialty glass. We can also offer thermal tempering for added strength. These capabilities, and more, make Swift Glass ideal for manufacturing glass applications for LED lighting and lighting systems.

Visit our lighting applications page for more information about our LED lighting glass capabilities, or contact us today.