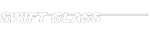

Glass wafers are thin, circular precision glass pieces, typically made from quartz, borosilicate glass, or fused silica. They are a necessary component for a variety of common electronics, such as electronic screen and display assemblies, and see use throughout a variety of industrial applications as well.

Swift Glass has nearly 100 years of experience delivering expertly fabricated glass parts. We employ the latest innovations in glass fabrication technology in conjunction with the highest-quality materials, enabling us to deliver reliable glass wafers. Read on to learn more about the glass wafer fabrication process, as well as the latest wafer trends.

The Glass Wafer Fabrication Process

At Swift Glass, our experts craft glass wafers that meet even the most challenging design requirements. The fabrication process involves five steps:

- Selecting Materials: Depending on each customer’s design requirements, an appropriate high-quality glass is selected. We work with borosilicate (including Borofloat®), quartz and fused silica. Borosilicate is highly affordable and retains excellent mechanical strength in challenging environments. Quartz is shock-resistant and features a high melting point.

- Cutting and shaping: After the materials have been selected, the cutting process begins. Using our advanced portfolio of glass machining equipment, we can cut orders up to 100,000 wafers.

- Edging and Detailing: Next, the glass wafers are further refined through edge grinding and detailing processes. The fabrication process uses carefully calibrated CNC diamond machine tools and each wafer is delicately machined to design specifications.

- Lapping and Polishing: We use a free abrasive lapping process to develop appropriate surface smoothness before polishing each wafer on both sides.

- Inspection: Wafers undergo a high precision laser inspection in a clean room to ensure that they fall within total thickness variation (TTV) standards.

Wafer Fabrication Trends & Challenges

Change and innovation in technology are constantly occurring. In wafer fabrication, the demand for thinner wafers has been increasing, causing manufacturers to adapt to the challenges this presents. Thinner wafers have edges that are more susceptible to chipping. This makes edge finishing processes to improve edge protection and decrease the likelihood of chipping necessary.

Using silicon materials has become another trend in wafer fabrication. Silicon has excellent thermal properties and can be more cost-effective than glass. However, glass wafers have certain unique advantages over silicon. For example, its transparency makes discovering any bonding defects much easier. Additionally, some temporary bonding polymers require transparent substrates, making glass the preferred material for these applications.

Many customers need to customize their glass wafers with finishes that include channels, cavities, or holes on the wafer surface. Swift Glass leverages value-added processes like ultrasonic machining and microblast machining to target highly precise areas of delicate parts. Ultrasonic machining removes small amounts of glass using high-frequency vibrations, without compromising the glass’s chemical or physical structure. Microblast machining can target substrates on a microscopic level to etch glass surfaces.

Glass Wafer Fabrication From Swift Glass

Swift Glass offers fully customized glass wafer fabrication for everything from prototypes to high-volume production runs. As an ISO 9001:2015- and ITAR-certified company, we use high-quality, reliable materials and the most advanced equipment available for each step of the fabricThis blog post discusses the glass wafer fabrication process and the latest trends in glass wafer fabrication.ation process.

Our capabilities include CNC machining, ultrasonic machining, microblast machining, thermal tempering, chemical strengthening, and more. For more information about our glass wafer fabrication capabilities at Swift Glass and how they will benefit your application, please contact us or request a quote today.