Glass can be strengthened using either heat or chemical treatments. The fundamental principle of glass strengthening is to create compression in the outer layers of glass while maintaining a state of tension in the interior glass. While tempering and heat treatments are often used to create the desired tension, chemical treatments offer a variety of benefits that can be tailored to particular applications.

As a premier provider of custom glass fabrication services, Swift Glass is pleased to offer an extensive selection of glass formulations and treatments for our customers in a wide range of industries. For nearly 100 years, we have been a leading provider of specialty glass products for everything from industrial glass to optics, photonics, and lighting. Our chemical glass strengthening formulations are specifically tailored to the glass formulation and intended final product for superior performance in nearly any application.

What Is Chemical Glass Strengthening?

Chemical glass strengthening uses chemical reactions to initiate ion exchange in the surface layers of the glass while encouraging tension in the inner glass. The combination of surface compression and tension strengthens the glass, making it more durable and less prone to breakage. Unlike heat treatments, such as tempering and annealing, chemical strengthening can be used on very thin glass and will not warp the surface, which makes it an excellent option for optics, windows, and other applications where distortion from thicker glass can affect performance.

Chemical treatments for glass strengthening typically include a molten salt bath of potassium nitrate. Potassium ions replace sodium ions on the glass surface. The slightly larger size of potassium ions compresses the particles in the surface, strengthening the surface on a microscopic layer and reducing the number of routes along which cracks can occur. The chemical composition of the bath can be modified and tailored to enhance certain properties based on the glass formulation or intended application.

Benefits of Chemical Glass Strengthening

Chemically strengthened glass offers a variety of unique advantages over tempered and annealed glass. Some of the primary benefits include:

- Enhanced Strength. Chemically strengthened glass is much stronger than heat-treated glass and provides a higher degree of break resistance.

- Durability. When compared with more conventional glass treatments, chemically strengthened glass exhibits a higher degree of resistance to abrasion, impact, and pressure.

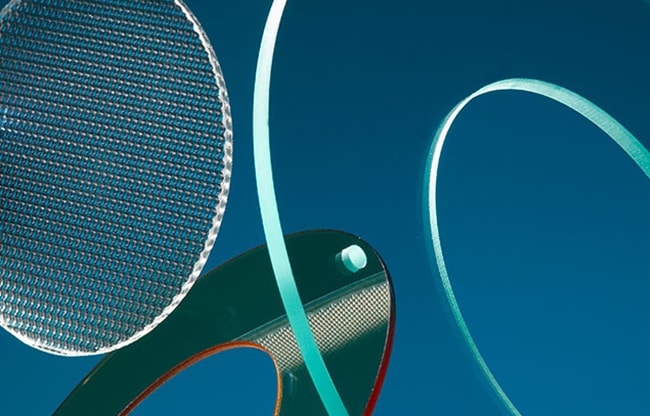

- Greater Versatility. Unlike with heat treatments, chemical strengthening can be used on thinner sheets of glass, allowing manufacturers to strengthen smaller, thinner, and more complex glass shapes and components.

- Temperature Resistance. Chemically strengthened glass displays a higher level of thermal resistance.

- Superior Quality. Glass that has been chemically strengthened provides exceptional strength with little to no optical distortion, leading to higher quality and unsurpassed optical clarity.

Uses for Chemically Strengthened Glass

The enhanced strength, optical clarity, and durability of chemically strengthened glass make it ideal for use in a variety of high-performance applications in the energy, communication, semiconductor, laboratory, and medical sectors. Its thermal stability and resistance to scratches and impact also make it perfect for windows in airplanes, railcars, boats, and automobiles. Chemically strengthened glass can withstand much greater pressure and temperature fluctuations, and is therefore used in industrial, marine, and military applications where there may be exposure to harsh conditions, broad temperature ranges, and high pressure.

Superior Chemical Glass Strengthening by Swift Glass

The experts at Swift Glass are committed to providing our customers in every industry with high quality specialty glass products tailored to meet even the most unusual and detailed specifications. With decades of experience, we have the knowledge necessary to ensure that all of our custom products meet and exceed industry standards with regards to size, strength, and overall quality. We are proud to serve a variety of industries including automotive, marine, military, semiconductor, optical, lighting, petrochemical, industrial, medical, and construction.

To learn more about our extensive selection of specialty glass products and services, contact us today or request a quote for your next project.