Parallelism as a parameter plays a crucial role in glass fabrication. As it pertains to glass, the back and front planes of a glass part would achieve parallelism if the space between the planes remained the same so that they run alongside each other but never touch. However, parallelism in actuality is not perfectly possible for glass parts, which is why a parallelism conversion tool or calculator can help measure accuracy for setting any necessary limits.

Defining Glass Parallelism

Glass parallelism, also termed glass wedge, can be determined through various measurements, including transmitted wavefront error (TWE), total thickness variation (TTV), and arcs (minutes and seconds). TWE is the amount of deviation in degrees observed in a wavefront due to beam transmission through an optical device. Parallelism, energy, and irregularity can all directly affect the total wavefront error.

TTV is the value of the difference from the maximum to minimum thickness values over a part’s clear aperture. An interferometer and a scan pattern can help define the value to within 0.1µm and therefore successfully manage a thickness variation of less than 1µm.

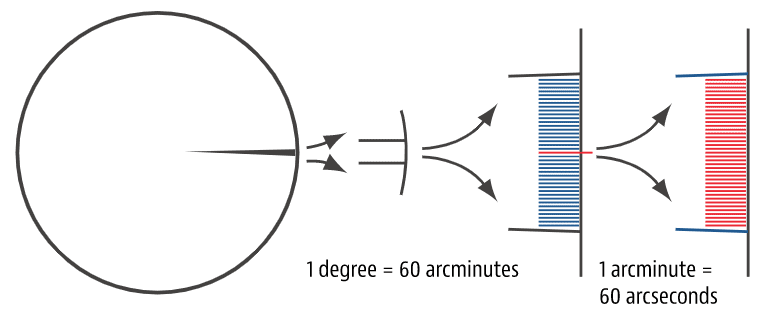

An arcminute is an angular measurement standard unit equivalent to 1/60 of a single degree while an arcsecond is equal to 1/60 of 1 arcminute, or 1/3600 degrees of a circle. Both minutes and seconds of arcs can translate, in degrees, to the amount that they deviate from full parallelism. Parallelism calculators can help you determine the definition of glass parallelism in surfaces to get an accurate measurement, which you can use to develop optical wedges.

Applications for Optical Wedges

An optical wedge is fabricated to possess a minimal angle between two glass planes or surfaces and refract or deflect light at that predetermined angle when it hits the wedge surface. The angle could represent only a fraction of a degree, approaching true glass parallelism, to as much as a 3° angle. Even though high-precision optics are usually lapped and polished to achieve near-perfect parallelism, most will still have a slight optical wedge that measures in seconds or minutes of arc.

Optical wedges come in different shapes and sizes, have different tolerances or coatings, and are mainly designed to change the direction of light and prevent reflections. Many industries have adopted optical wedges for applications such as:

- Beam steering

- Beam shaping

- Machine vision

- Telescopes

Optical Glass From Swift Glass

At Swift Glass, we provide comprehensive, precise optical glass fabrication services for projects that require large production runs in little time, without sacrificing quality as an ISO- and ITAR-certified company. Optimal performance is key in optical glass parts like lenses and optical windows, so we carefully consider the chemical and mechanical properties of the glass in addition to the optical factors like surface flatness, quality, and finish.

Swift Glass focuses on the proper levels of glass density, transparency, and purity. Our laser and imaging systems allow us to offer scratch-dig specifications to 40-20 in a variety of sizes, and in some specific instances, a scratch-dig of 20-10 is achievable. We also offer a selection of materials and color filters for customization.

Swift Glass has a newly created parallelism calculator to help with the conversion of degrees to arcminutes and arcseconds to best serve our customers. To learn more about our capabilities for optical glass or this conversion tool, contact us today or request a quote.