The Best Glass for UV Light Applications

Leave a CommentPeople often talk generically about ultraviolet (UV) light, but these rays are divided into three distinct types: UVA, UVB, and UVC. While we’re most familiar with UVA and UVB rays, which cause sunburns and may contribute to skin cancer, UVC rays—the most dangerous and damaging of all—are blocked by the atmosphere. This is a good […]

The Role of Glass in Astronomy and Space Applications

Leave a CommentIn the early 1600s, Galileo designed his first telescope based on his knowledge of earlier magnification technology from Dutch inventors. Since then, glass has continued to play an essential role in astronomy and aerospace applications. Common use cases for the material include optics in telescopes and windows in space vehicles. In both situations, the […]

5 Things You Didn’t Know About Swift Glass

Leave a CommentFor more than a century, Swift Glass has built a reputation on our company-wide commitment to excellence and customer care, which has led to our position as a worldwide leader in high-quality glass fabrication. We offer OEM solutions with a full range of capabilities, from glass cutting and machining to edge polishing, surface lapping, water-jet cutting, ink-jet […]

Pandemic Prompts Reshoring Trends for North American Manufacturers

Leave a CommentFor decades, U.S. manufacturers in nearly every industry have depended largely on offshore suppliers for raw materials, processed goods, and component parts. Even those companies that perform their own product assembly in the United States often rely upon imported components for their products. The COVID-19 crisis has revealed significant flaws in this strategy, as interrupted […]

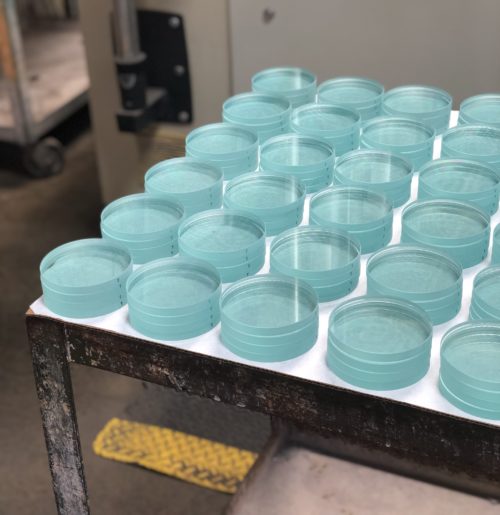

Sight Glasses for Oil & Gas Industry Applications

Leave a CommentSight glasses—also referred to as viewing glasses—are window elements that are installed in equipment to facilitate the observation of internal processes while maintaining the safety of the observer and the functional integrity of the system. The visibility offered by these components allows equipment operators to analyze ongoing processes and make better-informed adjustments to improve process […]

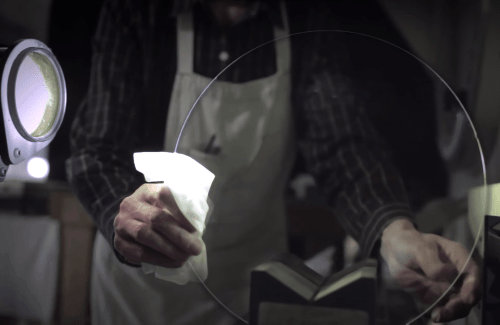

What is Optical Glass?

Leave a CommentThe optical industry encompasses a wide range of applications that relate to the properties and motion of light. From lenses for eyeglasses and cameras to fiber optics, optical solutions are a constant part of daily life. Optical glass is a fundamental material used in many optical applications, including prisms, lasers, beam splitters, and other optical […]

Glass Surface Quality vs. Surface Irregularity

Leave a CommentDuring the design and production of optical devices and systems, optical specifications—such as surface quality and surface irregularity—serve two key purposes: To set the acceptable limits for various performance parameters To determine the amount of resources required for production While an optical component may appear to be perfect—i.e., without defect—to the human eye, there may […]

5 Key Benefits of Fused Silica & Quartz

Leave a CommentFused silica and quartz are two commonly employed materials in glass fabrication operations. Both substances offer unique properties that make them suitable for use in fabricated glass components. The following blog post provides an overview of the two, including their composition, key benefits, and typical applications. Benefits of Fused Silica Glass Fused silica is a […]

Swift Glass Is Proudly ISO 9001:2015 Certified

Leave a CommentAs part of our ongoing commitment to providing customers with the highest quality products and services, the team at Swift Glass is proud to announce that we have been ISO 9001:2015 certified for almost 10 years. Here’s what this means for our customers. What Is ISO 9001:2015? Formed in 1947, the International Organization for Standardization […]