Over the past century, Swift Glass has established a reputation as a leading fabricator of precision glass products. As a pioneer in the glass industry, we have remained relevant and competitive by keeping abreast of the latest in glass machining technology. Our cutting-edge capabilities include precision glass computer numerical control (CNC) machining services and ultrasonic machining.

Over the past century, Swift Glass has established a reputation as a leading fabricator of precision glass products. As a pioneer in the glass industry, we have remained relevant and competitive by keeping abreast of the latest in glass machining technology. Our cutting-edge capabilities include precision glass computer numerical control (CNC) machining services and ultrasonic machining.

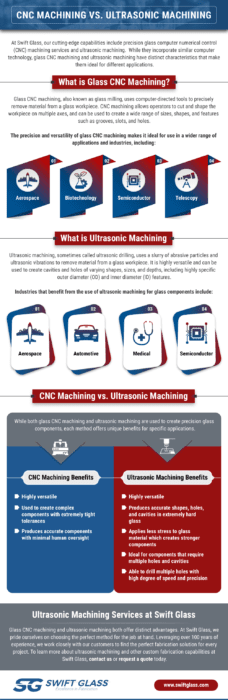

While they incorporate similar computer technology, glass CNC machining and ultrasonic machining have distinct characteristics that make them ideal for different applications. Below, we discuss the finer points of glass CNC machining vs ultrasonic machining to help you select the right process for your needs.

What is Glass CNC Machining?

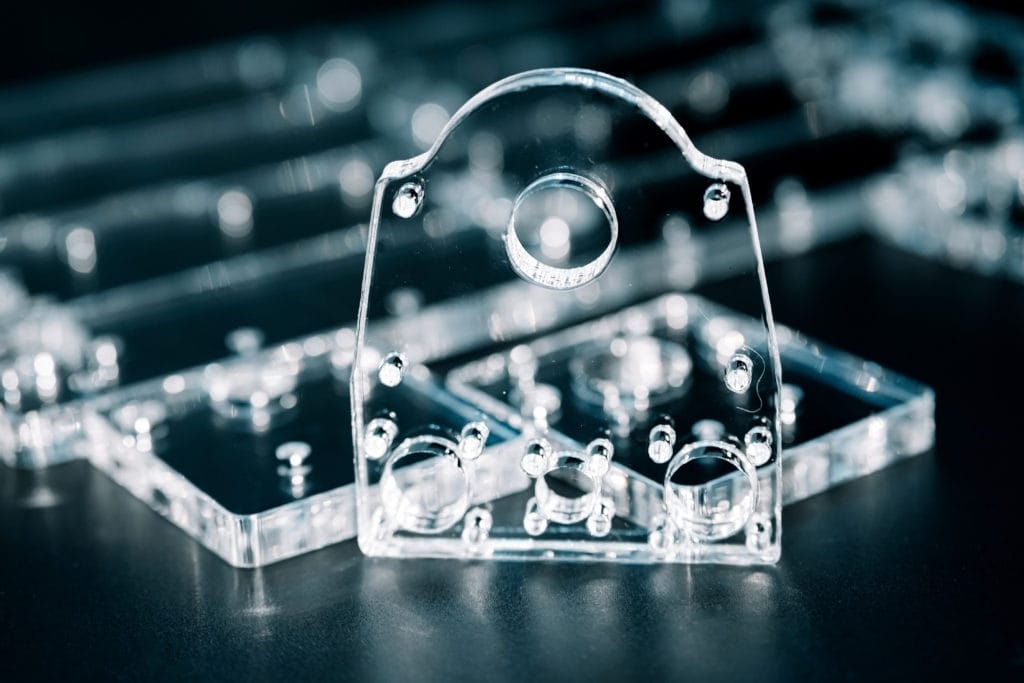

Glass CNC machining, also known as glass milling, uses computer-directed tools to precisely remove material from a glass workpiece. CNC machining allows operators to cut and shape the workpiece on multiple axes, and can be used to create a wide range of sizes, shapes, and features such as grooves, slots, and holes.

The precision and versatility of glass CNC machining makes it ideal for use in a wider range of applications and industries, including:

- Aerospace/ Defense: CNC machining is used to create gauges, instruments, and other components with complex shapes.

- Biotechnology: Biotech companies use CNC-machined components such as flow cells to facilitate material flow through precision channels and cavities.

- Semiconductor: The semiconductor industry uses precision CNC-machined glass for wafer stages, reference frames, mirrors, and lenses.

- Telescopy: Telescopes and microscopes require highly accurate and stabilized mirrors and lenses that can only be produced using precision CNC machining.

What Is Ultrasonic Machining?

Ultrasonic machining, sometimes called ultrasonic drilling, uses a slurry of abrasive particles and ultrasonic vibrations to remove material from a glass workpiece. Unlike cutting and milling, the slurry removes miniscule amounts at a time, finely grinding the desired shape into the glass. The slow abrasion eliminates the potential for stress buildup in the workpiece, conserving the crystalline structure and strength of the glass.

Ultrasonic machining is highly versatile and can be used to create cavities and holes of varying shapes, sizes, and depths, including highly specific outer diameter (OD) and inner diameter (ID) features. Industries that benefit from the use of ultrasonic machining for glass components include:

- Aerospace: Ultrasonic machining is used to create pressure sensors, flight instruments, and other sensitive glass components in airplanes and spaceflight equipment.

- Automotive: Ultrasonic machined glass forms high-grade sensors for proximity detectors, back-up applications, and other safety features.

- Medical: A variety of medical devices incorporate glass components that have been machined using ultrasonic methods.

- Semiconductor: The semiconductor industry regularly incorporates ultrasonic machined glass for wafers, electrodes, distribution plates, lenses, and mirrors.

CNC Machining vs. Ultrasonic Machining

While both glass CNC machining and ultrasonic machining are used to create precision glass components, each method offers unique benefits for specific applications.

Glass CNC machining is highly versatile and can be used to create complex components within extremely tight tolerances. CNC machining has the added benefit of producing accurate components with minimal human oversight.

Ultrasonic machining is capable of producing accurate shapes, holes, and cavities in even extremely hard glass that can be difficult to mill. Since it does not require direct pressure, heat, chemicals, or electricity, ultrasonic machining applies less stress to the glass material, facilitating stronger components ideal for critical applications and high-pressure operations.

Since ultrasonic machining does not deform or stress the glass, it is the perfect option for components that require multiple holes and cavities. The gradual removal of extremely small amounts of surface material allows ultrasonic machining to drill to exceptionally precise depths. Unlike CNC milling, ultrasonic machining can drill multiple holes with a great degree of speed and precision without compromising the integrity of the workpiece. For complex glass components with many holes, this can be an extremely effective and cost-effective method of mass production.

Ultrasonic Machining Services at Swift Glass

Glass CNC machining and ultrasonic machining both offer distinct advantages. At Swift Glass, we pride ourselves on choosing the perfect method for the job at hand. We remain at the forefront of the glass fabrication industry by incorporating the latest technology. Leveraging over 100 years of experience, we work closely with our customers to find the perfect fabrication solution for every project. To learn more about ultrasonic machining and other custom fabrication capabilities at Swift Glass, contact us or request a quote today.