Used to cut a wide array of materials across a range of industries, waterjet cutting is ideal for applications involving materials that are sensitive to the high temperatures generated by many other common cutting methods.

The phrase “waterjet cutting” is commonly used to refer to abrasive waterjet cutting, in which an abrasive such as granite is mixed in with the water stream. Softer materials, such as rubber, often employ pure waterjet cutting, where no abrasive is utilized.

In simple terms, waterjet cutting involves a high-pressure stream of water — with or without abrasives — that is used as a cutting tool. Thanks to its high precision and low-temperature operation, this method is used in many different applications, in fields ranging from mining to aerospace.

How Waterjet Cutting Works

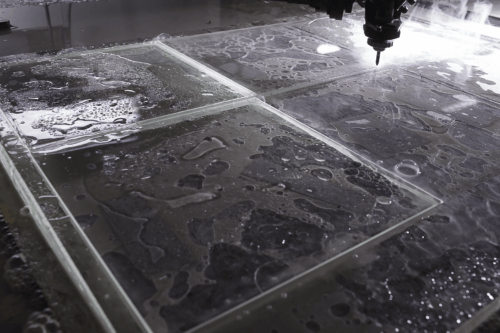

A waterjet cutting machine has two main parts. A high-pressure pump is used to generate a pressurized stream of water. This liquid then passes through an abrasive waterjet nozzle.

A waterjet cutting machine has two main parts. A high-pressure pump is used to generate a pressurized stream of water. This liquid then passes through an abrasive waterjet nozzle.

In this nozzle, water passes through a small-diameter orifice to form a precise jet. Abrasive granules are also added at this stage as needed.

Modern waterjet cutters have many additional control features, such as control systems for precisely managing the movement of the waterjet and articulating cutting heads that allow the waterjet additional freedom of movement in order to produce inclined cuts.

The water utilized is usually caught after cutting, as the energy must be dissipated. The machines also have storage hoppers for abrasive granules.

The high-pressure jet can be used to cut through materials such as glass, rubber, plastic, and stone. Essentially, any material that is softer than the abrasive used can be cut using the high-pressure stream.

In combination with specialized nozzles and articulating heads, this technique can be employed to provide intricate, highly precise cuts. The jet can also be varied to accommodate for the specific thickness and softness of the material being cut. This method offers many benefits over traditional cutting methods.

The Benefits of Waterjet Cutting

One of the most significant benefits of waterjet cutting is the high precision it offers. Since this technique utilizes a jet of water to create cuts, dimensions can be easily controlled, unlike other cutting tools.

This allows for smooth, extremely controlled cuts even in hard materials such as granite and glass. The precision and high degree of control offered make waterjets the preferred method for cutting gauges, solar panels, and ornamental products, as well as wafers for electronic applications.

And since waterjet cutters can easily handle hard material, they’re ideal for cutting high-pressure, explosion-proof glass and granite.

Also, the waterjet does not generate much heat while cutting, making this method well-suited to applications in which the material involved is temperature-sensitive, such as rubber. Waterjet does not alter the material properties of the substrate being cut and therefore does not generate a heat-affected zone.

Learn More

Highly precise and versatile, waterjet cutting can be used for a wide range of materials, even very thick ones. This method is especially well-suited for temperature-sensitive materials, and provides a smooth, controlled finish.

Swift Glass is proud to specialize in waterjet cutting. Utilizing two-axis and three-axis CNC equipment, we can provide material widths up to 9 inches and can cut to a precision of 0.1 mm. Our CAD-compatible software ensures optimal, consistent results. To learn more about our waterjet cutting services or discuss your specific application needs, reach out to the team today.

>”/>

>”/>