From aluminum and glass to acrylic and thermoplastic polyurethane, there are many options on the market for printer bed materials. However, it’s essential to choose carefully, as the quality of any 3D printed object starts with its first layer of substrate. For that reason and many more, glass has emerged as a top choice for 3D printer beds in recent years.

3D printing involves high amounts of heat that create warping and deformation in materials like plastic or aluminum. Suboptimal printer bed materials that are not completely flat can cause flaws in the first layer, dooming the project. Glass, specifically a special type called borosilicate glass, is ideal for 3D printing in a wide range of applications. Below, our team at Swift Glass explains in detail why this material is best for ensuring optimal part quality and performance.

6 Reasons to Print on Glass

Even if your 3D printer didn’t come with a glass bed, it may be worth the investment to replace and upgrade it. The price of glass to upgrade your printer bed should be the only cost, but the return on investment results in many benefits. Some of the many reasons to choose glass for a 3D printer bed include:

Even if your 3D printer didn’t come with a glass bed, it may be worth the investment to replace and upgrade it. The price of glass to upgrade your printer bed should be the only cost, but the return on investment results in many benefits. Some of the many reasons to choose glass for a 3D printer bed include:

1. One-time setup: Other materials require adhesion promoters that are one-time use only. The 3D printer glass bed needs only a one-time setup, as opposed to many printer bed materials that require periodic replacement and recalibration to level the bed.

2. Easy to clean: Glass is easy and quick to clean. Since glass has the perfect level of adhesion, it needs no promoters like glue or hair spray that must be cleaned and reapplied after each use.

3. Consistency: Aluminum printing beds are rarely completely flat even when new, and they continue to warp with heat or stress. Unlike aluminum or other materials, glass has less of a tendency to deform under pressure. Printing on an ideal flat surface like glass ensures the bed remains level after each print job.

4. Durability: Other alternative materials like Kapton tape, painter’s tape, and plastic print surface sheets are only good for one print job. Glass does not wear out, meaning you don’t need to worry about replacement.

5. Cost-Efficient: The price for glass is relatively low. Glass is flat, level, and durable, so there is rarely a need to replace it. When you consider that it leads to less waste, requires little maintenance, and rarely needs replacing, it is easily the most budget friendly option over time.

6. Effortless print removal: Some adhesion is vital to the success of your 3D printing project. However, too much can cause problems with the removal of the object. Glass naturally has the ideal surface adhesion for 3D printing, as it holds the item steady during the project, then easily releases it when completed.

Glass for 3D Printer Beds

Like any material, price and quality vary between types of glass. Soda-lime silicate is the least expensive. However, it contains air bubbles that make it less durable and more likely to crack under stress or heat. It is also vulnerable to chemicals, meaning that it can’t be cleaned with solvents.

The ideal 3D printer glass bed consists of borosilicate glass. This type of glass is a highly durable blend of silica and boron trioxide, chosen for cookware and lab equipment. It not only is chemical resistant, but it has no air bubbles, which means that it won’t crack when heated. Borosilicate glass is also consistently flat and smooth.

Because it has a low coefficient of thermal expansion, the removal of completed parts is effortless. Borosilicate glass expands minimally during heating and therefore contracts minimally while cooling. The contraction results in parts popping easily off the glass surface with no tools or force required.

3D Printing Bed Materials From Swift Glass

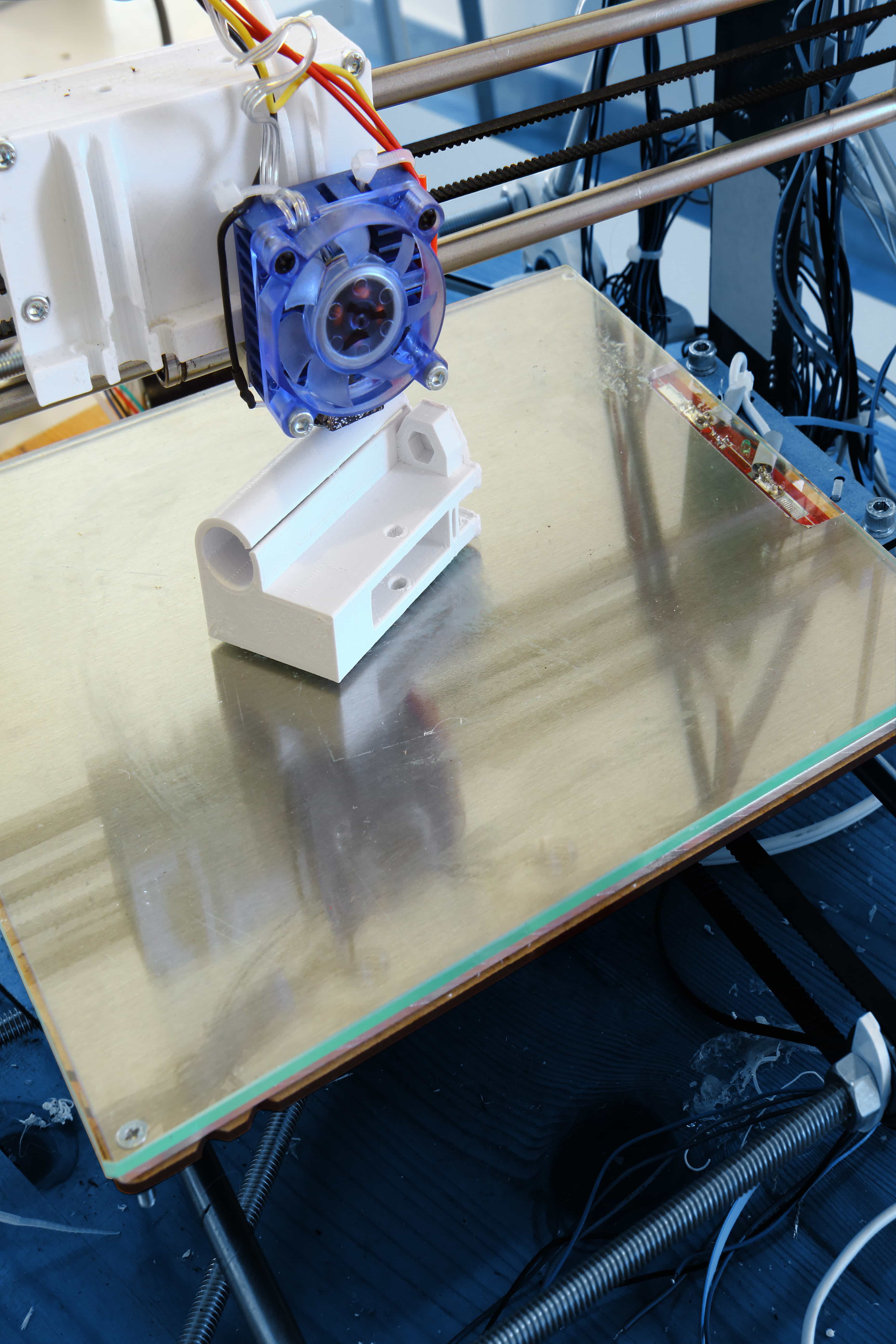

![]() 3D printing on a glass bed provides many benefits over traditional options. Borosilicate glass is a high-quality, consistently flat glass with supreme thermal shock and chemical resistance and a high level of durability under repeated stress. It is one of the most versatile 3D printing bed materials available, ensuring a level substrate to build consistently even layers.

3D printing on a glass bed provides many benefits over traditional options. Borosilicate glass is a high-quality, consistently flat glass with supreme thermal shock and chemical resistance and a high level of durability under repeated stress. It is one of the most versatile 3D printing bed materials available, ensuring a level substrate to build consistently even layers.

Swift Glass is an ISO 9001:2015 certified and ITAR registered company that is widely regarded as a leader worldwide in fabricating quality glass parts. We invite you to review our 3D printing portfolio to learn more about custom glass for 3D printing applications. For questions about the benefits of borosilicate glass in 3D printing applications, contact our team today.

1 Comment

Braden Bills

It’s interesting that you can have glass surfaces 3D printed. That seems like a great way to get the perfectly shaped glass! I can see why that would be popular to use for different implements.