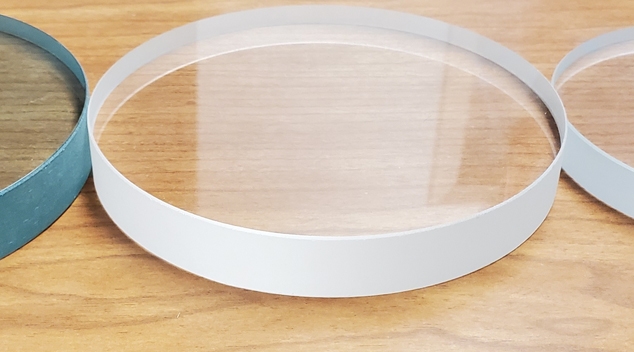

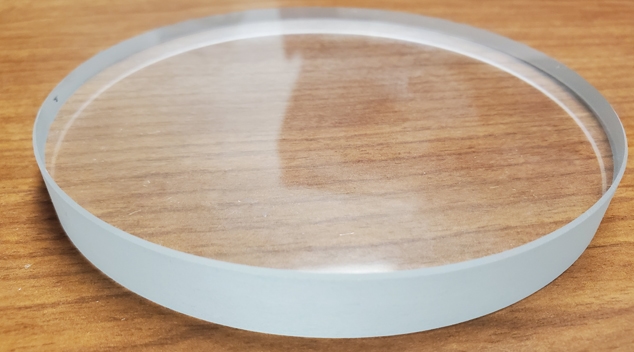

This is true for the oil, gas, and petrochemical industries more so than it is for any other. Sight glass for oil and gas applications is installed in many tanks, storage and active process tanks alike to allow for constant visual quality inspection.

High Pressure, High Reliability

Two similarities found across many oil, gas, and petrochemical production processes are the presence of chemicals and the use of high pressures.

Oil, gas, and other petrochemical processes require high pressures to be maintained at certain phases throughout the process. Extreme variations in pressure are also common. Sight glass has the potential to be a weak spot in an otherwise sound system.

In order to prevent loss of product or raw materials and, more importantly, to maintain worker safety, high-pressure sight glass should be used.

Request a Quote