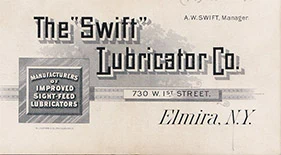

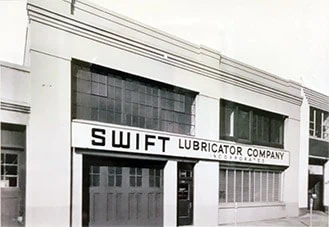

1881

Swift Glass begins as the Swift Lubricator Company founded by Allen Swift. The chief product was “sight-feed” lubricator used for lubricating parts of steam engines. Another main product was the “glass bowl oil cup”, which was also used in lubrication.

1938

Charles “Bud” Swift, son of Allen Swift, and Charles Burke invested to re-start Swift Lubricator (which had fallen under hard times because of the Great Depression in 1929). Products included “sight-feed” lubricators, glass reservoir oil cups, and water gages which were used as a glass tube to measure the fluid level in boilers.

1939

During World War II, Swift Lubricator becomes a sub-contractor of Timken Roller Bearing manufacturing products for trucks, tanks, and aircrafts.

1946

After the war, as America switched from a war-time to a peace-time economy, so too did Swift Lubricator make adjustments – pushing glass fabrication and purchasing glass saws and edge grinders.

1947

• Because of Swift Lubricator’s capabilities and Elmira Heights, NY location, Swift is chosen to be the distributor of Corning Glass’s Industrial Products division in New York State and New England.

1952

Charles Burke becomes the sole owner of Swift Lubricator.

1955

Kathleen K. Burke assumes presidency of Swift Lubricator upon the sudden death of her husband, Charles Burke.

1956

Charles “Ken” Burke, son of Charles T. and Kathleen becomes the General Manager of Swift Lubricator.

1959

Under Ken Burke, Swift begins to fabricate glass into many special and intricate parts. Machines were added to the facility and employment grew.

1963

- Daniel Burke, brother of Ken, joins the company.

- Swift Lubricator changes its name to Swift Glass Co.

1966

- At this point in time, Swift Glass’s primary focus was edge machining.

- Swift Glass buys out Eclipse Glass Company, which gives them many new capabilities allowing Swift Glass to be the first small company in the United States to offer tempering services.

- Dan Burke becomes president of the Eclipse Glass Division.

1970

- Swift Glass acquires International Optical in Long Island, giving them the capability to polish glass and opens the door for Swift Glass to enter the Optical Industry.

- Corning phases out their in-house finishing business of Pyrex® Glass Industrial products, and most of the finishing now comes to Swift Glass

1971

Swift Glass is named the only authorized source for tempering Corning’s Pyrex® Glass.

1980

Swift Glass becomes the polisher of choice of Pyrex® Glass blanks for Corning Glass.

1981

Swift Glass’s factory space increases by 100% in order to keep up with demand. The factory grows from 17,000 square feet to 35,000 square feet.

1988

Ken Burke passes away unexpectedly, and Daniel Burke becomes President, CEO, and sole owner of the company.

1990

“Just-in-Time” becomes the new demand – calling for small quantitates to reach customers just before they need to use the glass meant that their inventories lowered, and Swift’s lot size shipments are smaller, but more frequent.

1992

- Charlie Burke, Daniel’s son, the first employee of the 3rd generation of Burkes, joins Swift Glass.

- Swift Glass’s facility again increases with the addition of 15,000 square feet in order to handle increased entry into the optics business and to accommodate the moving of the Eclipse Glass division from Connecticut to Elmira, NY.

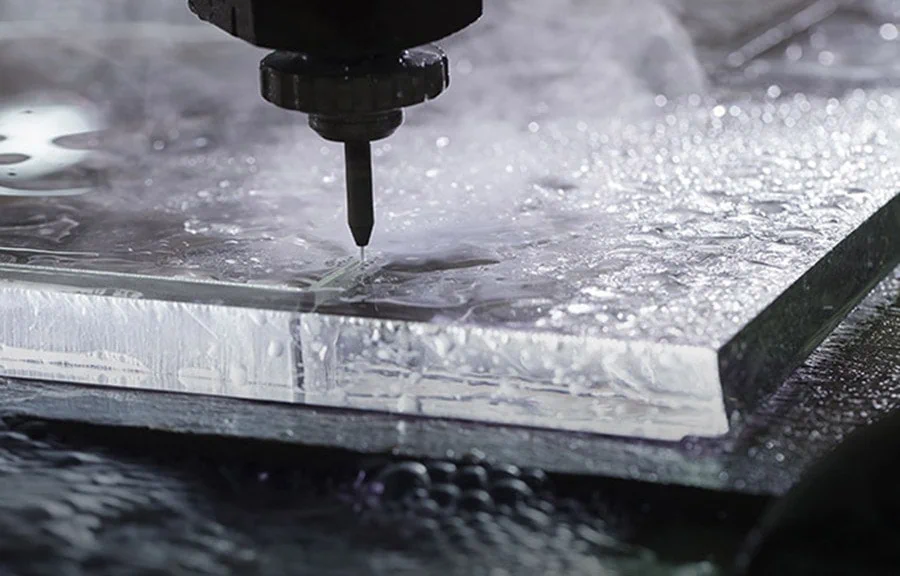

2000

- Optical development took a big step forward with the mastering of double-sided lapping and polishing

- Swift Glass introduces waterjet cutting – allowing the company to do more with Quartz and other hard materials.

2001

Swift Glass continues to grow – doubling the size of land they own. Kathleen Burke Schweizer joins Swift Glass.

2003

The latest building addition is completed on the newly purchased land to handle increased business in optics – bringing the current factory size to 75,000 square feet.

2005

Sheila Burke Reynolds begins at Swift Glass – the last of the 3rd generation of Burkes to join the company.

2016

Swift Glass adds Chemical Strengthening to their list of capabilities

2017

Swift Glass, an ISO 9001:2015 certified and ITAR registered company is a worldwide leader in the manufacturing of quality fabricated glass parts for a wide range of industries.

Have a question for our team? Reach out using the form below.