Borosilicate Glass

At Swift Glass, we are a world-renowned provider of high-quality fabricated glass parts. One of the materials we commonly work with is borosilicate glass, which is a specialized type of glass that contains high concentrations of silica and boron trioxide. Due to its impressive durability and thermal stability, it is used for the fabrication of everything from heat-tolerant laboratory glassware and scientific lenses to high-end lighting solutions.

What Is Borosilicate Glass?

Borosilicate glass contains boric oxide as well as several other ingredients in specific proportions. The inclusion of boric oxide results in a glass material with excellent thermal properties. The material has a very low coefficient of thermal expansion and very high resistance to thermal shock. As a result, it retains its dimensions across different temperatures and resists cracking and shattering when exposed to rapid temperature changes.

Is Borosilicate Glass Safe?

Compared to other types of glass, borosilicate glass offer a number of safety advantages, such as:

- Thermal stability: As mentioned above, borosilicate glass can tolerate extreme temperature fluctuations owing to its low coefficient of thermal expansion and high resistance to thermal shock. These qualities make it an ideal material for products such as sight glass since it can handle the sudden transition from heat or pressure to cool without breaking.

- Environmentally friendliness: Borosilicate glass is a more sustainable material option than plastics since it is made from naturally occurring raw materials that are relatively abundant and easy to acquire.

Borosilicate Glass vs. Soda-Lime Glass

Soda-lime glass is the most common type of glass, accounting for approximately 90% of all glass manufactured across the globe. While it is made from similar materials as borosilicate glass, it has different material proportions. This difference in composition results in distinct characteristics that make the materials suitable for different applications. For example:

- Borosilicate glass is harder, which allows it to be fabricated into more intricate and complex shapes.

- Borosilicate glass is more resistant to chemicals.

- Borosilicate glass is more thermally stable, which allows it to withstand use in applications where it is subjected to high then low temperatures.

In terms of cost, soda-lime glass is generally more readily available and more affordable than borosilicate glass. However, the many benefits provided by borosilicate glass often make it worth the price, especially in applications where durability, heat tolerance, and chemical resistance are essential for product performance and safety.

Applications of Borosilicate Glass

Borosilicate glass’s strength and durability make it a preferred material choice for numerous industrial and commercial applications. Examples of typical uses include:

- Scientific lenses and hot mirrors: Due to its low coefficient of thermal expansion, borosilicate glass maintains the same optical properties across a range of temperatures, making it an ideal material for scientific lenses and other high-precision optical components. This type of glass is also used in the fabrication of hot mirrors, which are designed to protect sensitive optical systems by reflecting infrared light.

- Thermal insulation: Borosilicate glass can be used to withstand high temperatures when compared to soda lime in severe applications.

- High-intensity lighting: Glass receptacles and membranes used in high-intensity lighting systems are often made from borosilicate glass, which allows them to tolerate the intense heat generated during continuous operation. Examples of lighting products with borosilicate glass components include high-intensity discharge (HID) lamps and studio or stage lighting.

- Sight glass: Borosilicate glass is commonly fabricated into the high-strength sight glasses or viewing windows that are incorporated into tanks, boilers, and other high-heat industrial systems. These windows allow workers to monitor internal processes without having to open the receptacle or interfere with the operation.

Borosilicate Glass Varieties at Swift Glass

At Swift Glass, our custom products are fabricated using high-quality glass materials from reputable manufacturers. Our borosilicate glass selection includes:

- CORNING® EAGLE 2000®: This lightweight glass material has a low coefficient of thermal expansion and low density. Additionally, it offers excellent transmissivity, flatness, and surface quality.

- CORNING EAGLE XG®: This environmentally friendly glass material offers high surface quality, low density, and excellent thermal and chemical properties.

- SCHOTT BOROFLOAT® 33 Glass: This environmentally-friendly, lightweight float glass combines excellent transmission with superior chemical & thermal resistance, is suitable for anodic bonding and exhibits a high surface hardness and low inherent fluorescence.

- SCHOTT D263®: This thin borosilicate glass has low alkali content produced with extremely pure raw materials making it highly chemical resistant. It has excellent surface quality that can be coated without any post-process surface work.

- SCHOTT SUPREMAX®: This rolled glass material has identical properties to SCHOTT BOROFLOAT® 33 Glass. It is 12% lighter than soda-lime glass.

Our team can fabricate these materials in various ways to meet the part specifications and standards of our customers, including:

- Edge grinding and polishing: We refine and smooth edges or add intricate dimensional details to parallel and perpendicular tolerances of ±.005 inches.

- Thermal tempering: We improve the durability, temperature resistance, and shatter resistance of borosilicate glass products for use in harsh environments and safety-critical applications.

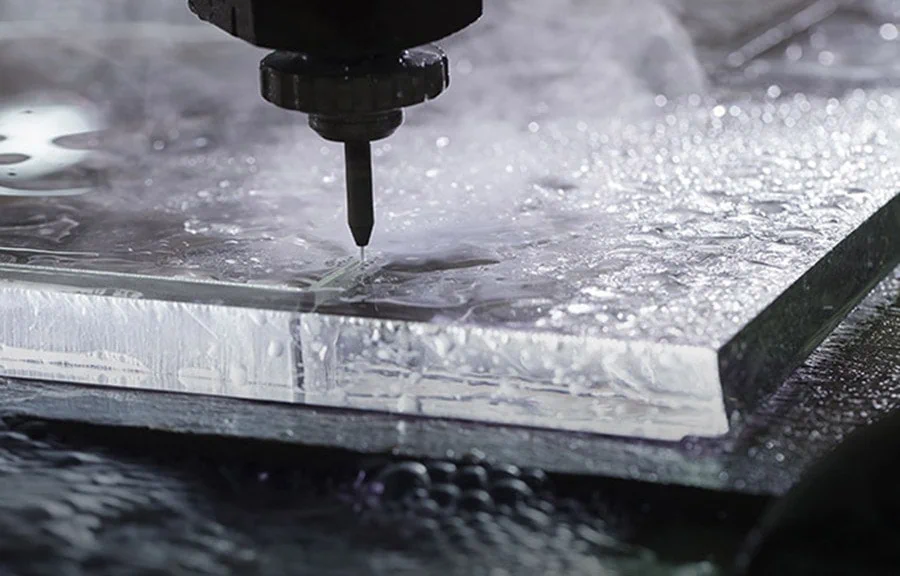

- Waterjet cutting: We cut the material into the necessary shape or size for the desired glass part.

- CNC machining: We offer a variety of machining services for materials up to 27 inches (wide) by 48 inches (long) by 8 inches (thick), including boring, engraving, drilling, slotting, pocketing, surfacing, and grooving.

- Cutting and drilling: We use diamond-tipped drill bits to cut precise holes into materials with thicknesses of up to 0.75 inches.

- Surface lapping and polishing: We offer manual and CNC lapping and polishing services. Small components can be processed on one side, while precision optical parts can be processed on both sides.

- Glass wafer fabrication: We use a combination of precision shaping, edging, detailing, and polishing to produce high-quality borosilicate glass wafers that meet high design standards in a range of technical and industrial applications.

Learn More About Borosilicate Glass From the Experts at Swift Glass

Given its many advantageous characteristics, borosilicate glass is an excellent material for numerous industrial and commercial applications. That’s why the experts at Swift Glass often use it to fabricate parts for customers.

Want to learn more about borosilicate glass and how it can benefit your next project? Swift Glass is here to help! Equipped with over 100 years of glass fabrication experience, we have the knowledge and skills to help you understand and take advantage of this material’s superior mechanical and thermal properties. We also stock fused silica glass, quartz, and other specialty glass materials, which gives us the flexibility to meet virtually any glass fabrication request.

To learn more about borosilicate glass materials or our glass fabrication capabilities, contact us. To discuss your fabricated glass needs with one of our experts, request a quote.