Manufacturing Strengthened Glass for Extreme Environments

Leave a CommentHigh-intensity industrial processes call for durable equipment that will prove resistant in the face of even the toughest of applications.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

If you’re carrying out procedures against harsh or extreme conditions, it’s essential that your application is equipped with the proper glass component. Tempered safety glass in windshields, for example, provides extra security in the event of breakage.

High performance glass is required to withstand a vast range of pressures, elements, and external factors, each of which vary by industry. When operating in high intensity environments susceptible to extraneous factors, it’s important to be aware of common concerns that can arise.

Below are a few common risks associated with extreme industrial climates, along with the glass strengthening solutions that help reduce those risks:

High-Pressure Exposure

One of the most frequently noted stress points for high performance glass, this can manifest itself in marine, architectural, and even aeronautical environments.

Strengthened glass, however, can help prevent or reduce the adverse effects of high pressure. In addition, strengthened glass helps shield your work environment from harm caused by explosions, bullets, and projectile aftermath, each of which may pose a threat to safety and productivity. Safety glass offerings, like tempering, can help to ensure a less devastating effect upon impact than with regular glass.

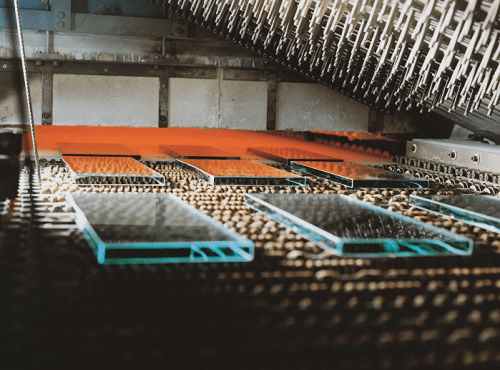

Extreme Temperatures

Exposure to extreme temperatures can result in potentially adverse effects upon operations. Fortunately, heat-treated glasses can offer dramatically increased protection against hazards like thermal shock. Heat treatment offers glass—a material often susceptible to high temperatures—increased protection against high-temperature breakage.

Harsh Environments

Exposure to intense, abrasive elements or harsh, wet and extreme environments holds the potential to work against high performance glass. For certain extreme or outdoor environments, heat-tempered glass may not be necessary, but it can provide exceptional resistance against thermal stresses and extreme wind pressure. Fully tempered glass, however, can offer unparalleled safety when it comes to ensuring safety break pattern. If operations are under harsh weather conditions, tempered glass ensures your work environment remains both active and safe.

Learn More in Our eBook

At Swift Glass, we’re dedicated to providing consumers with the high quality materials they need for safe, efficient, and effective day-to-day procedures. For additional information regarding glass strengthening solutions, access our new eBook titled Creating Glass That Withstands Extreme Environments.

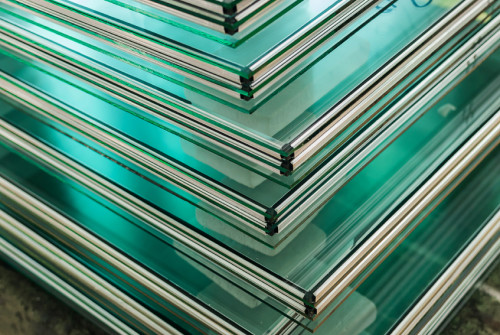

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.

But not all glass is the same, and our ability to modify glass and improve its qualities is what allows us to use glass in applications where it would have been a safety hazard.