Mining Industry’s Growth Signals a Surge in Demand for Advanced Glass Well Plugs

Leave a CommentThe mining industry is entering a transformative era as it evolves from a traditionally manual and labor-intensive field into a tech-forward powerhouse fueled by automation, data, and advanced materials. To further this change, mining operations need smarter solutions that enhance efficiency, safety, and sustainability.

Two major trends are shaping the new direction of mining. One is the rise of “smart mining” technologies and the other is increased need for well services in exploration and operations. Together, these forces are driving a notable increase in demand for specialized components, such as Swift Glass’s temporary tempered glass well plugs. These advanced tools are uniquely designed to meet the challenges of modern mining head-on. Keep reading to learn more.

A Surge in Well and Drilling Services

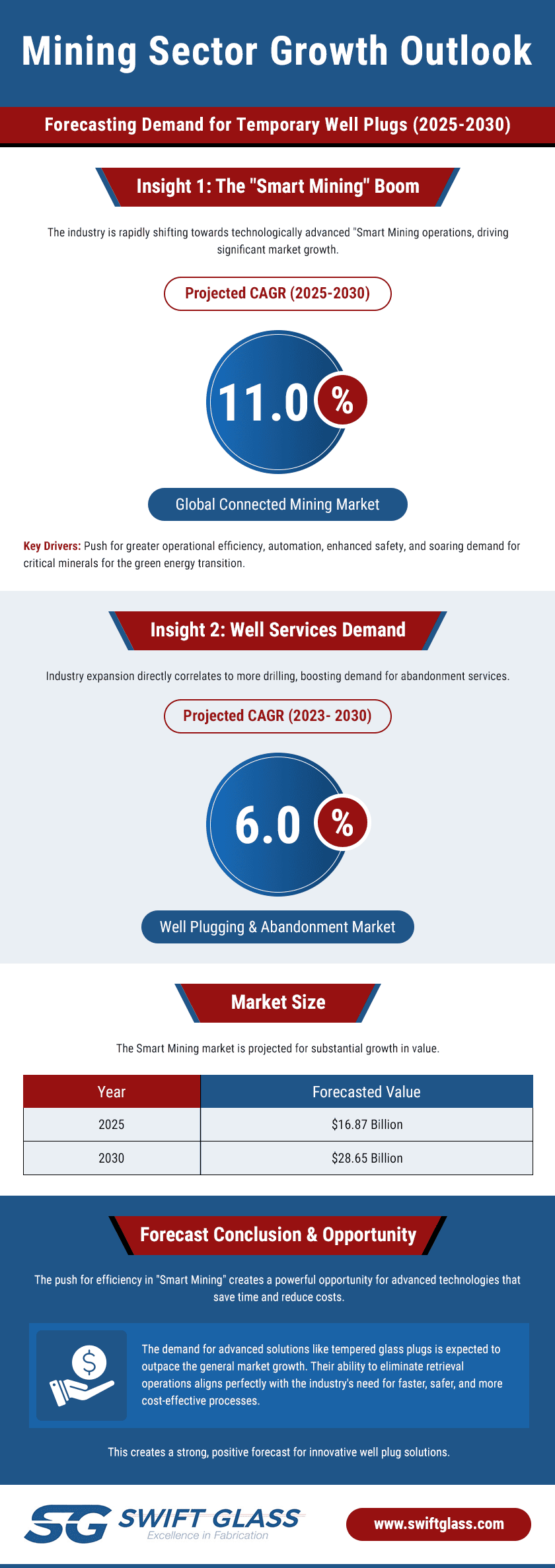

As global demand for minerals rises, mining operations are expanding in both scope and sophistication. In fact, the mining industry as a whole is projected to grow at a rate of 5.7% CAGR by 2030. This growth directly translates into more ground-level activity, particularly drilling wells for exploration, dewatering, and geotechnical evaluation.

All wells eventually need to be temporarily or permanently sealed. This means well abandonment services are an essential part of the mining life cycle. The market for well plugging and abandonment services is forecast to grow at a steady CAGR of around 6.0% through 2030, according to GMI Research. While much of this growth pertains to permanent closures, it also reflects an increased demand for temporary well management solutions that support modern, staged project planning.

The Macro View: The Smart Mining Revolution Is Here

“Smart mining” refers to integrating technologies, such as AI, IoT, cloud-computing, and real-time analytics, throughout the mining value chain. It’s not merely a buzzword. Smart mining represents a seismic shift toward increased automation, cost reduction, and enhanced worker safety.

The global connected mining market is projected to grow at a compound annual rate of 11% between 2025 and 2030, according to Grand View Research. Three primary forces are propelling this growth:

- Efficiency Mandates. Declining ore grades and rising operational costs demand faster and leaner processes.

- The Green Energy Transition. The urgent global push for electrification and renewable technologies creates an unprecedented appetite for critical minerals like lithium, cobalt, and rare earth elements.

- Regulatory and Safety Pressure. Companies are under increasing pressure to reduce workplace hazards and comply with evolving environmental and safety standards.

These drivers are accelerating the adoption of high-tech tools and processes across the mining landscape. But they also create secondary pressures: legacy equipment and outdated processes, such as mechanical well plugs that require costly and risky retrieval, can become major obstacles to efficiency.

Why Advanced Plugs Are Set to Outperform Old Designs

The convergence of smart mining’s explosive 11% projected growth and the 6% forecast for well abandonment services reveals a significant opportunity well plug production and sales. But there is a potential bottleneck: traditional mechanical plugs often require retrieval processes or drilling to remove, which means extended downtime, increased labor costs, and heightened safety risks.

Swift Glass’s tempered glass plugs are a strategic alternative. Created through a precise thermal glass tempering process, these plugs are engineered to withstand the extreme temperatures and pressures of downhole environments. They also incorporate a controlled shatter design that allows them to break apart cleanly when triggered. As a result, these advanced plugs eliminate the need for removal.

Temporary tempered glass plugs have a number of benefits for mining and well abandonment operations, including:

- Less unplanned downtime.

- Enhanced worker safety.

- Streamlined planning for multi-stage wells.

- Lower overall project costs.

Proven effective in oil, gas, and petrochemical applications, these plugs are now positioned as a key enabling technology for mining operations that are pursuing faster, smarter workflows. And because they directly support the goals of smart mining, their market growth is likely to outpace even the baseline 6% CAGR seen in the broader well services category.

Meeting the Moment with Advanced Materials

The need for smarter well management doesn’t end with digital dashboards and predictive analytics. Physical components like well plugs must evolve in tandem with software and computer-driven tools and equipment. To stay competitive, mining operations need tools that match the speed, safety, and sustainability standards set by smart mining principles.

At Swift Glass, we’ve developed tempered glass for the mining industry and controlled shatter glass well plugs specifically for this future-focused approach. These plugs offer:

- High strength-to-weight ratio.

- Predictable, safe disintegration.

- Compatibility with aggressive downhole conditions.

- Simple deployment with no retrieval required.

Get Ahead with Solutions from Swift Glass

The data tells a compelling story: the mining industry is growing fast, and it’s getting smarter. As the sector embraces automation and AI, the demand for intelligent, efficiency-boosting components is skyrocketing.

For mining companies ready to step into the future, now is the time to act. Contact Swift Glass to learn how our cutting-edge solutions can help you stay ahead of the curve in a rapidly evolving market.

Securing the Pause: How Tempered Glass Revolutionizes Temporary Well Abandonment in Mining

Leave a CommentThe mining industry relies on innovative materials and technology to improve key processes, such as sealing wellbores. The wellbores can contain multiple sections to be mined sequentially. After a section has been completed, it must be sealed off to prevent pressure loss while fluids are pumped from other areas.

Finding the safest and most cost-effective way to secure a well is crucial. Tempered glass plugs are an innovative and extremely effective solution to these challenges, offering durability, safety, and reliable protection.

The Strategic Advantage of the “Pause”: Why Miners Use Temporary Well Abandonment

Temporary well abandonment is a strategic tactic used to put a well into a holding pattern between drilling operations and completion. It differs from drilled-but-uncompleted (DUC) wells in that it is a planned phase in mining operations that can safeguard the wellbore’s integrity while it remains in a holding pattern. This practice is beneficial for several key reasons:

- Supports batch completion. In large-scale mining projects, operators drill multiple wells sequentially. By temporarily abandoning each one as they drill new areas, it’s possible to seamlessly complete the drilling phase and then have completion crews handle all wells simultaneously for improved efficiency.

- Prevents logistical and equipment delays. Mining operations require an extensive amount of machinery that can be delayed or may require repairs. Temporary abandonment is a cost-effective way to pause operations when problems with equipment or processing facilities occur.

- Helps mining companies navigate fluctuating market conditions. When fluctuating commodity prices become unfavorable, immediate extraction can become unprofitable. In these situations, pausing a well allows mining companies to safely wait for improved market conditions without losing their investments.

The Swift Glass Solution: Controlled Shatter With Tempered Glass Plugs

Traditionally, metal or composite material plugs have been used to block off wellbores. However, creating these plugs is expensive and time-consuming. They require extensive drill-out and retrieval operations. Removing a traditional plug is labor-intensive and hazardous to workers. A more effective alternative is to use shatterable tempered glass plugs.

This innovative solution is made from durable tempered glass that withstands a wellbore’s high-pressure conditions yet breaks down as needed under designated conditions. The thermal glass tempering process for these glass plugs creates immense compressive stress on the core’s surface and tension. This makes the glass as much as four times stronger than standard glass.

Tempered glass plugs are resistant to impacts, thermal shock, and the corrosive downhole environments that oil, gas, and petrochemical mining sectors experience. However, the plug’s most important quality is their ability to “shatter” when no longer needed. Instead of simply breaking, the tempered glass safely disintegrates into a fine powder.

Crucially, this controlled disintegration eliminates the need for plug retrieval. With tempered glass plugs, the glass fragments are small enough to be circulated out of the wellbore along with the fluid, resulting in reduced labor costs, significant time savings and reduced downtime, and improved safety.

Key Mining Applications for Temporary Well Plugs

Temporary well plugs are suitable for many mining environments, including:

- Dewatering wells. These wells are designed to lower groundwater levels so that mining operations can occur. They are often paused during specific project phases.

- Exploratory drilling. Drilling test holes is an important first step in mining projects. Exploratory drilling assesses the mineral potential of an area and must often pause temporarily while data is analyzed.

- Geotechnical investigation. Mine planning often requires multiple wellbores to explore an area’s soil and rock mechanics. These wellbores must be safely paused as other areas are explored.

- Zonal isolation. Complex wells involve multiple geological zones and staged extraction phases. Temporary well plugs safely isolate certain areas as needed.

Explore Quality Temporary Well Plugs From Swift Glass

Temporary well abandonment is a safe and cost-effective operational strategy for mining operations. With innovative tempered glass well plugs from Swift Glass, the process is faster and more effective than ever before. Swift Glass’s controlled-shatter well plugs are not only safer for personnel, but can even reduce operational costs and project downtime. Leading with nearly a century of experience in glass fabrication, Swift Glass products deliver proven results.

Learn more about our advanced thermal tempering capabilities by reaching out to our team. To get started on improving your mining operations, request a quote today.