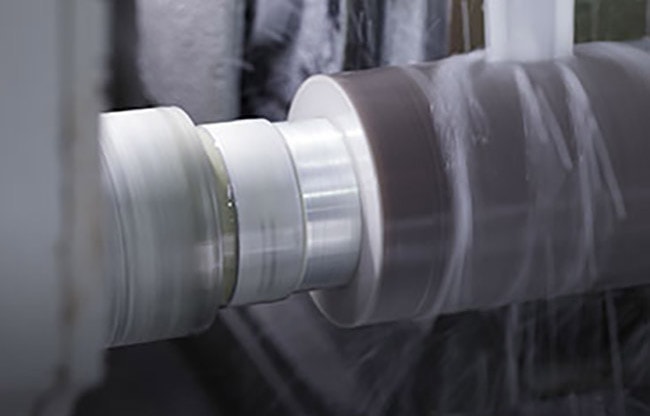

Optical glass is used for lenses, prisms, and mirrors in a range of applications from cameras to microscopes to beam splitters. It is extremely clear, has low levels of dispersion, and its refractive index can be fine tuned during the manufacturing process. These qualities make it well-suited to high-precision instrumentation and equipment.

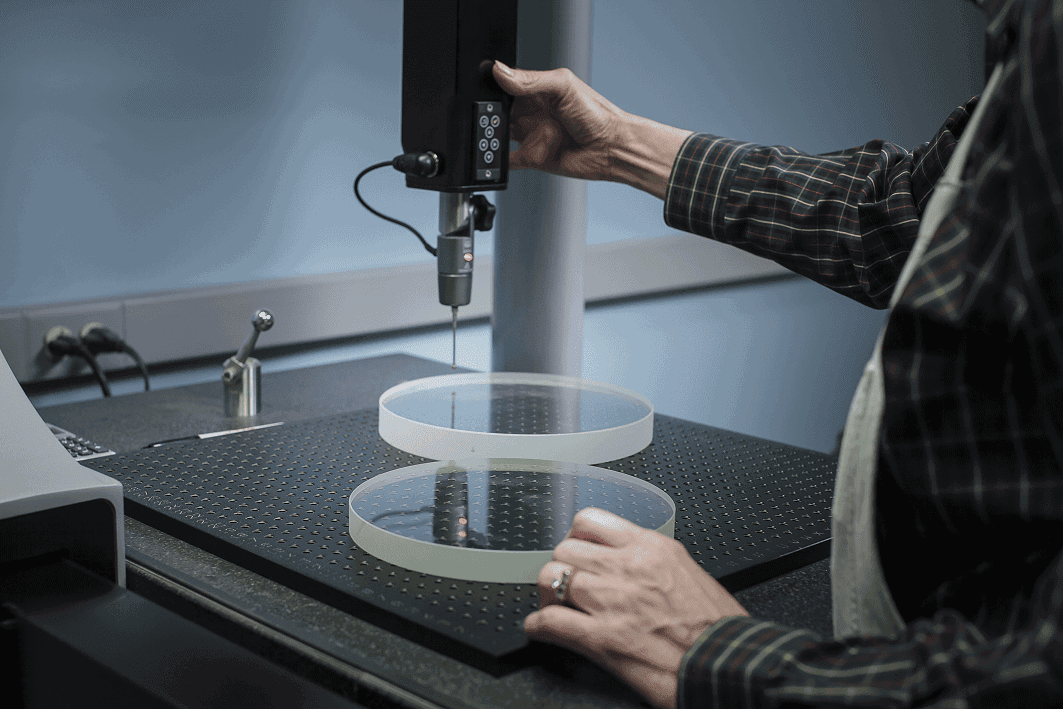

If optical glass components fall outside of acceptable tolerances, the entire application is put at risk for inaccuracy, poor image quality, or faulty data. Careful inspection of lenses, prisms, and mirrors is critical to ensuring their integrity. At Swift glass, we use a variety of advanced optical metrology and inspection techniques to validate and test our optical glass products. One of these techniques is laser interferometry, which is vital for measuring surface form and flatness. Learn more about this process and how we apply it.

Swift Glass: Advanced Interferometry Capabilities for Your Glass Needs

Swift Glass uses a laser interferometer to achieve reliable, high-resolution measurements. These systems are known for their speed, sensitivity, and ability to detect sub-wavelength deviations. As a result, we are able to provide our customers with glass components that perform reliably in the most demanding environments.

We’re committed to precision at every stage of production. Our interferometric capabilities reflect that commitment by helping us maintain industry-leading quality standards. Here’s what you can expect when you partner with our team:

- Premium Glass Materials. We use high-grade fused silica and quartz, known for their superior homogeneity and thermal stability. Blanks are inspected using interferometry early in the process to ensure they are suitable for downstream operations.

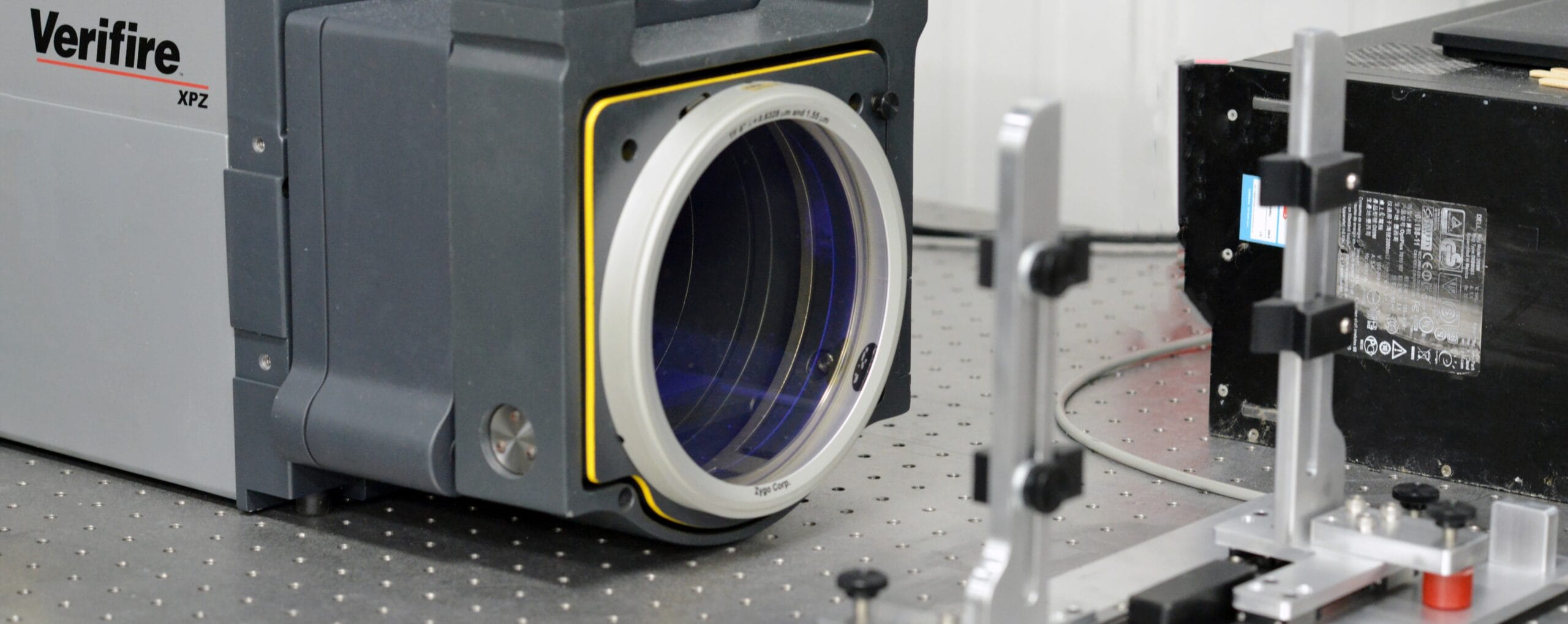

- State-of-the-Art Equipment. We use the ZYGO Verifire™ Laser Interferometer, a high-performance system designed to measure surface form error and transmitted wavefront distortion. It allows us to:

- Detect nanometer-scale deviations in surface quality.

- Perform fast, repeatable measurements.

- Inspect both small and large components with precision and accuracy.

- Support for Many Applications. Our interferometric inspections support a wide range of industries and use cases, including:

- Optical glass for infrared cameras.

- Sensor covers requiring extreme clarity.

- High-precision optics in laser applications.

- Color correction elements for deep wavelength control.

- Inspection for Larger Glass Components. Our laser interferometry setup features a six-inch aperture, allowing for the accurate inspection of larger glass parts. This gives us an edge in projects requiring oversized or thick components, without losing accuracy.

Tools to Assist You

If you are looking for help with specifying the right glass or inspection standard for your application, check out our website. It provides tools and resources to guide your selection process, including:

- Degree to arcminute to arcsecond conversion tool

- Micron to fringe to wave conversion tool

- PSI calculator for sight glass discs

- Flatness conversion table

Contact Us for Quality Custom Glass Solutions

At Swift Glass, laser interferometry is a vital component of our comprehensive inspection capabilities. When combined with other advanced methods, this tool enables us to deliver custom glass solutions that meet the most strict standards and tightest tolerances.

We are ISO certified and committed to manufacturing excellence. From building a prototype to launching full-scale production, our team works to ensure that your optical glass components meet and exceed industry standards and expectations. Contact us today for more information or request a quote to start your next project.