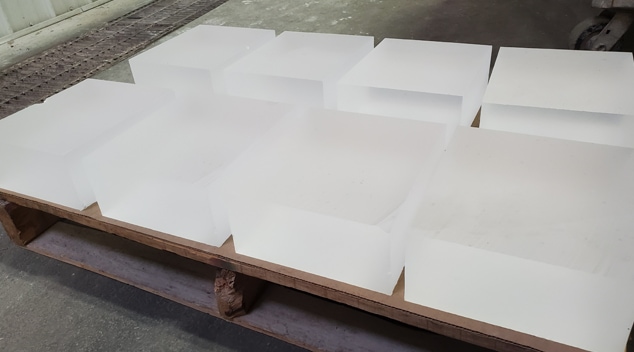

Our vast inventory of materials allows us to accommodate any request, no matter its complexity or scale.

Materials stocked include:

- Aluminosilicate – A glass that is able to withstand temperature over 1300 degrees Fahrenheit. Found in steam boilers, lamps and combustion tubes

- Borofloat® – Offers outstanding thermal resistance, exceptionally high transparency, high chemical durability and excellent mechanical strength

- Diamant – A type of float glass used in interior applications requiring highly transparent materials

- Flat Gauge Glass

- Furnace Observation Cobalt Blue – Protects against harmful UV & IR rays

- Fused Quartz and Silica – Provides excellent resistance to chemicals

- Infrared Reflecting Glass – Blocks infrared rays, keeping the equipment operator cooler

- Optiwhite

- Pyrex®

- Soda Lime Float – Principally used in wafers, touch screens, data discs and microscope slides

- Starphire – Glass that contains low mineral content and is enjoyed for its clarity

- Tubing & Rod

- Tubular Gauge Glass

- Vycor® – Resistance against high thermal shock, and can be fabricated in multiple shapes and sizes

Our industrial components are currently utilized by OEMs, construction, aerospace, and aviation industries. In addition, we are well equipped to provide a host of manufacturing and fabrication services. It is our goal to deliver these services in a timely and cost efficient manner.

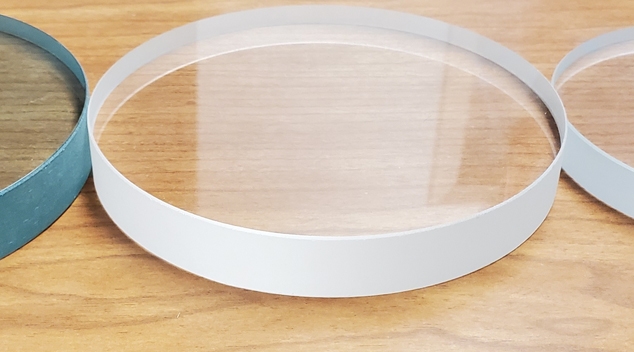

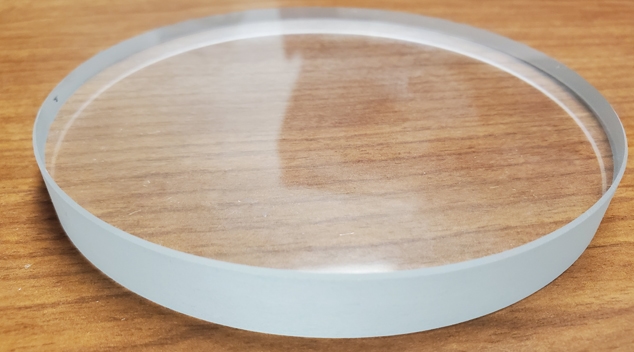

Our current manufacturing capabilities can accomplish:

- A flexible range of diameter and thickness tolerances

- Customer oriented results and solutions

- Ability to accommodate large volume requests with short lead times

In addition to the above offerings, we vigorously test our designs to ensure they exceed our clients’ quality expectations. Through the implementation of random sample inspections and measuring quality metrics with tools such as a Polarimeter, we are able to guarantee that the products we deliver to you will perform at the highest level.

For more information, contact a glass expert today. Our team of experienced engineers and technicians are looking forward to assisting you with your next project.