Surface lapping smooths a glass substrate using a type of cutting tool shank called a lap. The surface of the lap is covered with abrasive materials and scrubs the workpiece to reach the desired thickness or shape and can remove damage caused by previous manufacturing operations, such as sawing. Polishing is a finishing process that uses specially designed polishing cloths or abrasive films to smooth the surface of the workpiece to the desired finish. At Swift Glass, we offer surface lapping and polishing to deliver finishes on glass pieces to precise specifications.

Surface Polishing

Surface polishing relies on fine abrasives to remove material from a surface, producing a blemish-free finish. Polishing can incorporate specialized lapping plates, abrasive films, or polishing cloths applied to the workpiece surface at low speeds. There are two surface polishing methods for glass workpieces: single or double-sided. When determining whether single-sided polishing or double-sided polishing is ideal for an application, it is vital to consider the application and glass part design.

- Single-sided polishing: This method polishes only one side of the workpiece while protecting the other side from contact with the polishing tool. Single-sided polishing is best suited for applications that require different polish levels on each side of the material, parts that require only one polished side, large pieces, and asymmetrical finishes.

- Double-sided polishing: This method polishes each side of the substrate equally using abrasive granules suspended in liquid. Double-sided polishing provides a superior surface finish using planetary motion. It is ideal for rough surfaces, exacting parallelism, wavefront error transmission, and surface finish quality. The polishing technique is less stressful and is suitable for most optical materials.

Lapping Process

A lap is comprised of soft material and fine abrasives. The lap scrubs the surface of a workpiece with light pressure and can be performed with a hand lap or machine. Hand lapping relies on manual means to polish the workpiece using a lapping plate. A worker gently scrubs the workpiece over the plate containing a pastelike coating of abrasive material.

Machine lapping uses a rotating lapping plate with several retaining rings that rotate in unison with the plate to prevent workpiece slippage. Depending on the application, the abrasives can be in liquid or powder form. Machine lapping can quickly finish large volumes of parts. It removes material from the workpiece in microscopic chips to provide a superior finish.

Precision lapping provides the following benefits:

- Tight tolerance

- Precise surface finish

- Consistency

- Flatness

- Reduces camber

- Parallelism

- Polishing preparation

Industries Served

Various industries depend on surface lapping and polishing from Swift Glass. Our clients include leaders in the following industries:

- Aerospace

- Automotive

- Biomedical

- Energy

- Industrial

- Lighting

- Marine

- Military & Government

- Optical

- Petrochemical

- Semiconductor

Precision optical glass requires surface lapping and polishing to reach precise tolerances, flatness, and surface finishes.

Surface Lapping & Polishing From Swift Glass

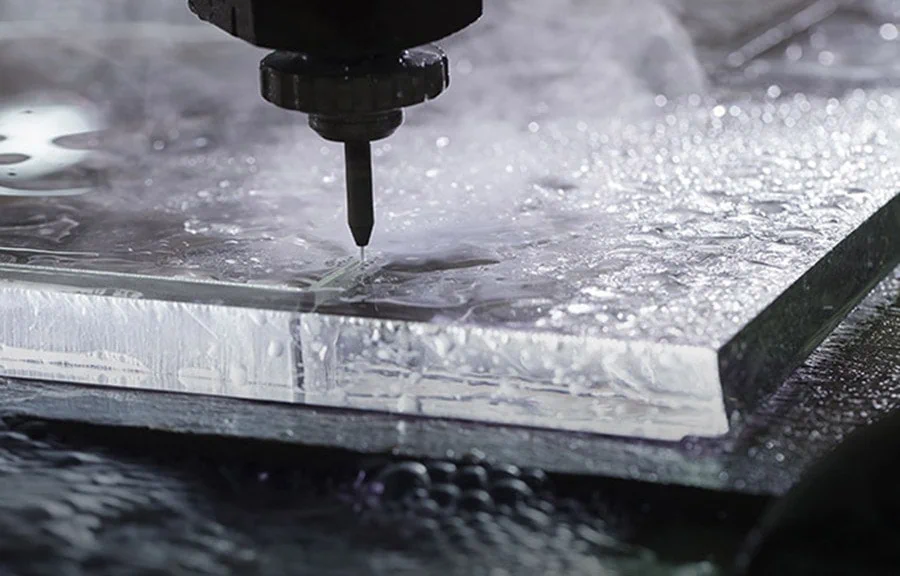

Swift Glass has been a leader in quality glass fabrication and manufacturing for nearly 100 years. We rely on in-house bending, thermal tempering, polishing, waterjet cutting, edge grinding, chemical strengthening, drilling, silk-screening, decorating, and ink-jet printing for our glass fabrication. We work with established glass manufacturers like SCHOTT, GE, and Corning.

Surface lapping and polishing deliver glass products with a smooth, appealing finish executed to precise tolerances and specifications. At Swift Glass, we provide lapping and polishing services to diverse industries, including semiconductor, medical, and optical. Contact us to learn more about our surface lapping and polishing services or request a quote today.