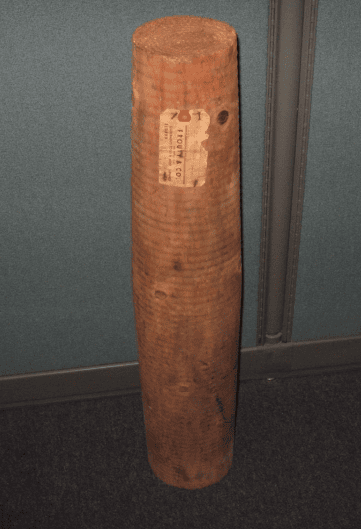

Pre - 1878

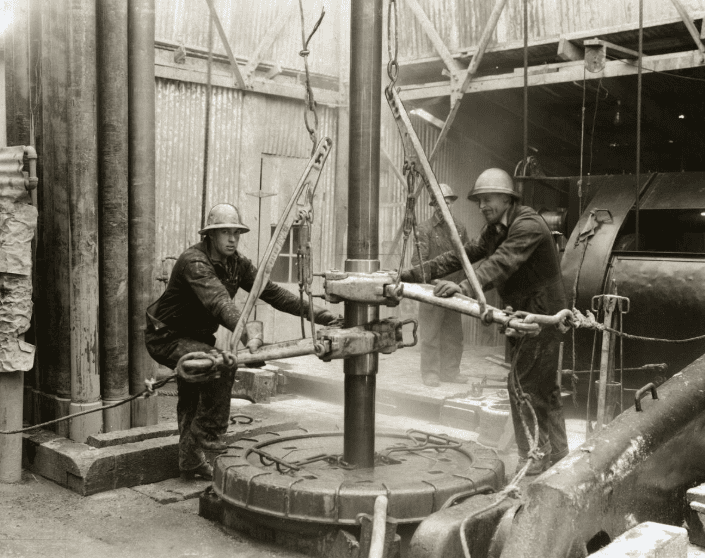

Unregulated BeginningsIn the early days of oil and gas exploration, there were no laws for sealing wells. When a well was abandoned, operators salvaged the valuable steel casing and backfilled the hole with rudimentary materials like wood, rocks, and field debris. The primary goal was not environmental protection, but to prevent water from contaminating the valuable oil or gas resource below.

1878 - 1920s

The Dawn of RegulationReacting to issues like migrating gas, Pennsylvania passed the first plugging laws, mandating the use of wood plugs and sediment. This era established the basic engineering concept of creating a “bridge” (often a wedged log or tree) inside the wellbore to support the fill material above it.

1920s - 1950s

The Rise of CementTechnology advanced significantly with the adoption of cement, which could create a true, permanent hydraulic seal. Regulations became more sophisticated, requiring the isolation of individual geological zones. This period also saw the rise of a separate practice—mine sealing—to combat acid mine drainage from horizontal mine entries using concrete walls and traps. The era culminated with the API publishing formal standards in 1952, cementing cement’s role as the industry standard for permanent well abandonment.

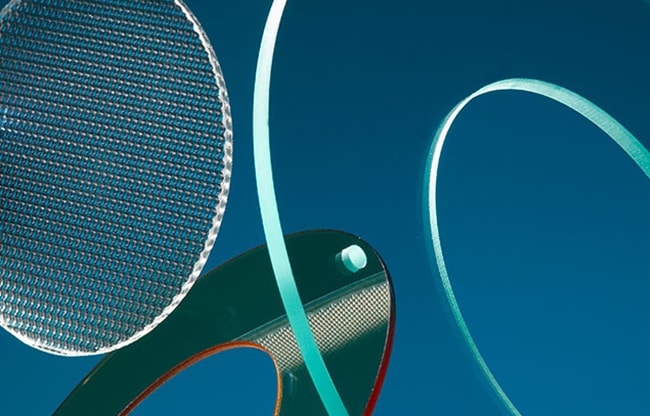

Early 20th Century

Engineered Safety ComponentGlass first proved its industrial worth in harsh environments. It was used in miner safety lamps to provide critical illumination in dangerous, gassy conditions. The invention of borosilicate glass (like Pyrex) by Corning in 1908 to solve the problem of shattering railroad signal lanterns demonstrated that glass could be engineered for extreme thermal and chemical resistance. These applications established glass as a reliable safety material.

1944

The Military Precedent: Controlled ShatterDuring WWII, German engineers created the Glasmine 43, an anti-personnel mine made almost entirely of glass to be undetectable by metal detectors. Critically, the mine’s fuze was activated when the thick glass pressure plate was crushed. This was the first major application where glass was engineered not for its durability, but for its specific mode of catastrophic failure. It established the key concept of “controlled shatter”.

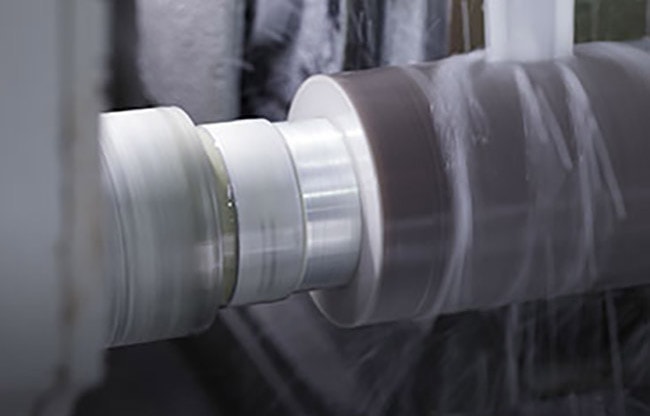

1960s - 2010s

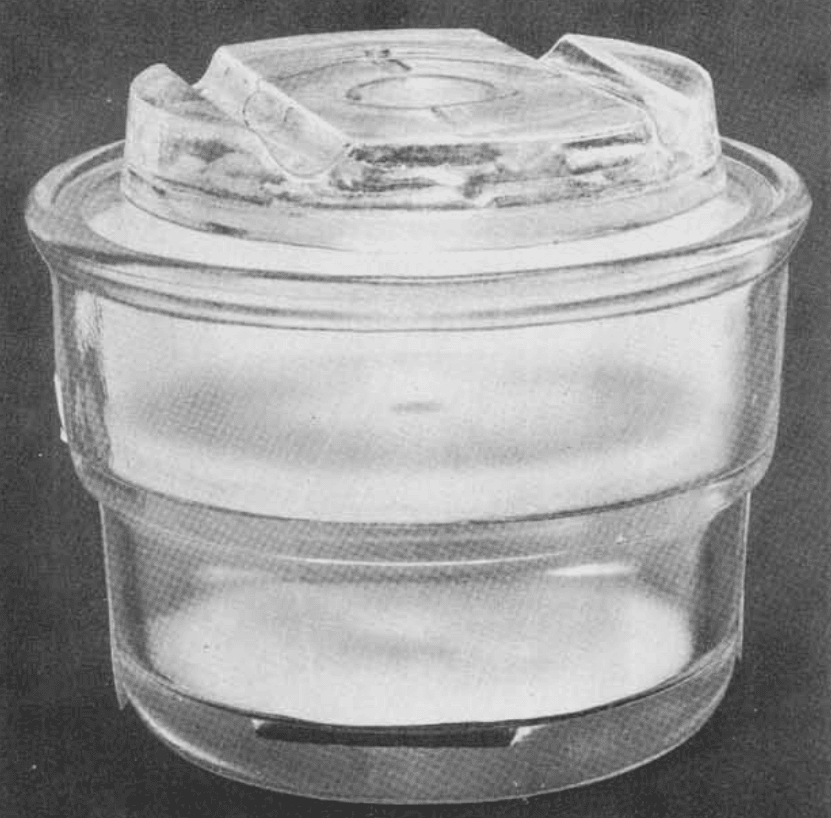

The Enabling Technology: Tempered GlassThe industrial maturation of the thermal tempering process was the final key step. Tempering makes glass up to four times stronger than standard glass but also causes it to disintegrate into small, dull, cube-like pieces when it fails. This unique combination of high strength and a predictable, total failure mode provided the exact properties needed for a temporary well plug: strong enough to hold pressure, but easy to remove completely on command.

2010s - Present

Commercialization of the Modern Glass PlugBuilding on a 2015 patent for a crushable glass barrier plug , tempered glass plugs were commercialized and adopted by the mining industry. Driven by the need for efficiency in “smart mining,” these plugs solve a major bottleneck created by traditional mechanical plugs, which require risky and time-consuming drilling for removal. Glass plugs are now used for temporarily abandoning wells during phased projects, isolating geological zones, and dewatering, allowing for greater operational flexibility and lower costs.

2017

Swift Glass, an ISO 9001:2015 certified and ITAR registered company is a worldwide leader in the manufacturing of quality fabricated glass parts for a wide range of industries.

Have a question for our team? Reach out using the form below.