What is Dispersion in Optics?

Leave a CommentIn optics, dispersion refers to light that is separated by individual colors as it passes through an object. Rainbows are the most common example of this event. The rainbow forms when white light is separated into components of different wavelengths (or colors). Dispersion can result in signal degradation in many applications, especially over large distances.

Dispersion in Optical Fibers

There are three types of dispersion: modal, chromatic, and material.

Modal Dispersion

Modal dispersion refers to the path taken by a ray of light. Many transmitters emit multiple mode types. Some of the light rays travel through the fiber while others reflect off of the fiber core’s boundary, instead traveling along an indirect path on the waveguide. These constitute the two types of modes: high-order modes and low-order modes.

- High-order modes enter the fiber at acute or obtuse angles, and take significantly longer to pass through fiber than low-order modes.

- Low-order modes enter the fiber directly and pass through it more quickly.

Modal dispersion can be eliminated by using a single-mode fiber. These fibers only transmit one mode of light, so the signal won’t be spread through modal dispersion.

Chromatic Dispersion

Chromatic dispersion results from the emitter’s spectral width, which determines the number of wavelengths that are emitted—the smaller the spectral width, the fewer wavelengths. Longer wavelengths move faster than shorter ones, so they arrive at the end of the fiber quicker to spread out the signal. Chromatic dispersion may be decreased by narrowing the transmitter’s spectral width. A monochromatic emitter has just a single wavelength, so it does not contribute to chromatic dispersion.

Chromatic dispersion is important to researchers who design optical equipment, including cameras, optical microscopes, and telescopes. The system in such equipment must be carefully planned—which includes using a combination of lenses made of different materials with different indices of refraction—so that the chromatic aberrations are minimized, resulting in an optimal image.

Material Dispersion

Material dispersion occurs when the wavelength depends on the refractive index of the fiber core material. Material dispersion is a contributing factor to a number of phenomena, including:

- Waveguide delay dispersion

- Chromatic aberrations in lenses

- Group delay distortion

- Color separation in prisms

- Multimode group delay spread

- Differential mode delay

Metrology manufacturers rely on glass prisms to disperse light in precision equipment, such as spectrometers.

Glass Fabrication from Swift Glass

If you’d like to learn more about optical dispersion, you can pick up our free eBook, “Understanding the Optical Properties of Glass.” It provides an in-depth look at key properties that affect the optical performance of your glass material, including the refractive index, chromatic dispersion, and transmission/transmittance. Knowing this information is especially vital for engineers who work in industries in which the optical performance of glass is key to meeting application specifications.

If you’d like to learn more about optical dispersion, you can pick up our free eBook, “Understanding the Optical Properties of Glass.” It provides an in-depth look at key properties that affect the optical performance of your glass material, including the refractive index, chromatic dispersion, and transmission/transmittance. Knowing this information is especially vital for engineers who work in industries in which the optical performance of glass is key to meeting application specifications.

Swift Glass is an ISO 9001:2015-certified and ITAR-registered company with nearly 100 years of experience in the industry. Custom glass fabrication is our specialty, and we are known for our company-wide commitment to providing quality solutions for original equipment manufacturers. We work with leading glass manufacturers—including Corning and Schott—and we stock a wide range of materials, allowing us to quickly respond to your needs. We have provided solutions for companies in the biomedical, industrial, optical, and aerospace industries.

If you are in need of glass fabrication services, be sure to contact our team to request a quote today.

Understanding Glass Properties: The Absorption Spectrum

Leave a CommentFor engineers who work with glass parts or components, there are many important properties of glass to understand. In previous posts, we have covered several different properties of glass, including transmittance, transmission, and refractive index.

- Transmission and transmittance are both ways of measuring the amount of light that can pass through a material without being absorbed.

- Refractive index is a measurement of the velocity at which light travels through a material.

Absorption is another key property of glass. In this post, we will go over what absorption is, and what factors change the absorbance of glass. With this information, you will be able to make an informed decision about the right glass for your application.

What Is the Absorption Spectrum of Glass?

Light is made up of photons. When a photon hits a material, it can emit energy that matches the amount required to excite an electron into a higher energy state. This will cause the photon to be absorbed by the material and not pass through it.

Light is made up of photons. When a photon hits a material, it can emit energy that matches the amount required to excite an electron into a higher energy state. This will cause the photon to be absorbed by the material and not pass through it.

When talking about glass specifically, we typically want as few photons as possible to be absorbed. As photons are absorbed, the intensity of the light on the other side of the glass is reduced. The absorbance factor of glass measures how much the intensity of the light decreases when it passes through the glass.

A material with high absorption, such as a neutral density filter for a camera, can dramatically decrease the intensity of the light passing through. This can be very useful in some situations, and very unwanted in others. If your application calls for as much light as possible to be let through, you will want a glass that features low absorption. If your application is being used to block light or reduce its intensity, you will want to select properties of glass to increase absorption.

What Factors Change the Absorbance of Glass?

There are three main factors that impact absorbance:

Thickness

Thickness is the easiest factor to understand and control. The more time it takes light to travel through glass, the more likely it is that a photon will excite an electron and be absorbed. By reducing the thickness of the material, you increase the amount of light that can pass through.

Composition

Glass reacts to light differently based on its chemical composition. Completely clear glass, for example, absorbs between 2-4% of the light that passes through it, while prismatic glass absorbs between 5-10%. Different formulations of glass have different properties, and a glass chosen for its strength or impact resistance may not have the best optical clarity.

Wavelength

Certain wavelengths of light react with specific materials and increase their absorption. For example, take a green piece of glass. If a red light shines on green piece, it’s likely that almost no light would pass through. Shining a white light would cause a moderate amount of light to pass through. If you shine a green light onto the green glass, however, almost all of the light would pass through the material. When looking to block a certain wavelength of light—as in many darkroom applications, for instance—you would choose glass that has a high absorption of that specific wavelength.

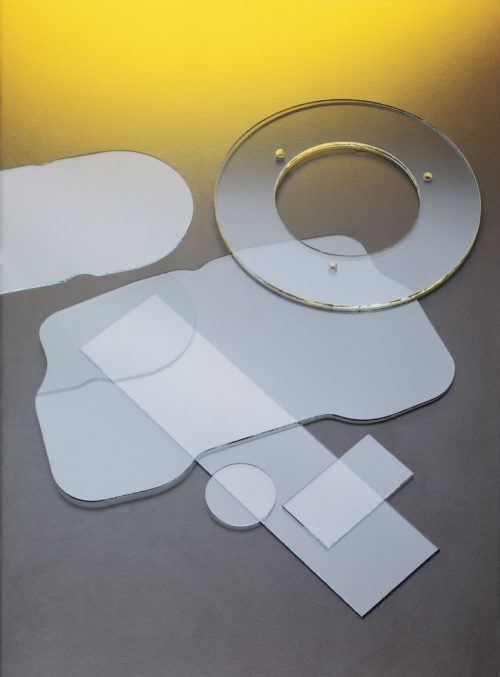

Swift Glass’s Capabilities

Swift Glass caters to customers across many different industries with a wide variety of different application needs. We offer a wide range of services, such as:

- CNC glass machining

- Waterjet and glass cutting

- Thermal glass tempering

- Polishing

- Grinding

- Chemical glass strengthening

- Surface polishing

- Lapping

- Glass drilling

- Glass wafer fabrication

We ensure optimal quality for all of our customers, so we have a wide variety of inspection tools at our disposal. We use a coordinate measuring machine, polarimeter, optical comparator, and high powered microscopes to check the optical properties of all of our products.

If you need more information about the properties of glass, or are ready talk to us about your application, request a quote today.

Single-Sided vs. Double-Sided Polishing

Leave a CommentIn many industrial applications, glass must be polished in specific ways to achieve the correct optical properties. Glass polishing offers an ideal solution for glass components that require a high level of precision, as polishing uses very fine abrasive particles to polish surfaces to a superior finish.

The Differences Between Single-Sided vs Double-Sided Polishing

There are two types of polishing: single-sided polishing and double-sided polishing. Which type is most appropriate depends upon the specifics of the application and design.

Single-Sided Polishing

Single-sided polishing machines move one surface over the workpiece, grinding away at only the top surface while keeping the bottom surface protected. Single-sided polishing is ideal when:

- Two surfaces of the work need to be polished to different requirements

- When parts only require polishing on one side

- Polishing large parts (the workpiece can be flipped to polish the other side if necessary)

The process of polishing is quite complex, especially when the highest levels of accuracy and precision are required in the finishing of a piece. It is important for manufacturers to analyze and control the wear of the polishing surfaces. Any irregularities or worn machines can damage the finish of a piece.

Double-Sided Polishing

Double-sided polishing is performed on both sides of a piece at once. Fine abrasive particles are suspended in a liquid which is used to wear away the top and bottom surfaces of a piece of glass. Planetary action on the part of the top and bottom plates results in excellent surface finish, including:

- Transmitted wave front error

- Parallelism

- Surface quality

- Surface roughness

Because the two sides of the work piece are abraded equally, it reduces stress on the material and is ideal for most optical materials. Double-sided polishing is best when:

- Two sides of a piece must be exactly parallel and equal in finish

- Parts have very specific flatness requirements

- Design requires the highest available surface quality in factors such as parallelism and flatness

Single-Sided and Double-Sided Polishing Services with Swift Glass

At Swift Glass, we offer both single-sided and double-sided polishing services. Precise parallelism and high flatness are important requirements for many optical applications. We offer the services to meet those needs. Swift Glass possesses capabilities for both high- and low-volume projects with a combination of manual operations and computer-controlled machinery.

Swift Glass has the services you need to achieve the correct precision and surface finish on your glass parts. We are experts in both single- and double-sided polishing and can help you determine which is correct for your application.

For more information on our polishing services, please request a quote today.