Using cutting-edge technology and strict quality assurance processes, Swift Glass delivers precision medical glass components that meet these strict demands.

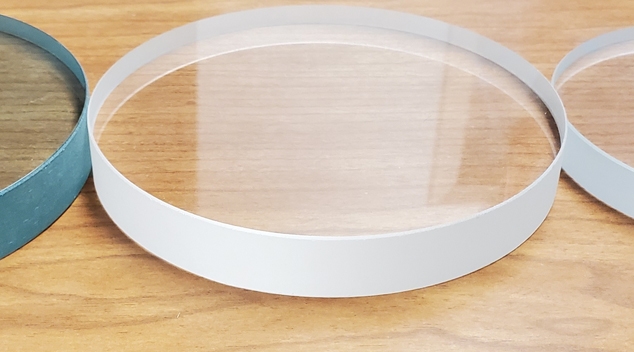

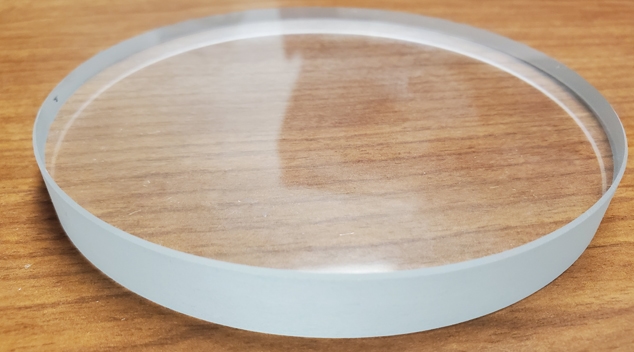

Surface Lapping and Polishing for Extreme Flatness

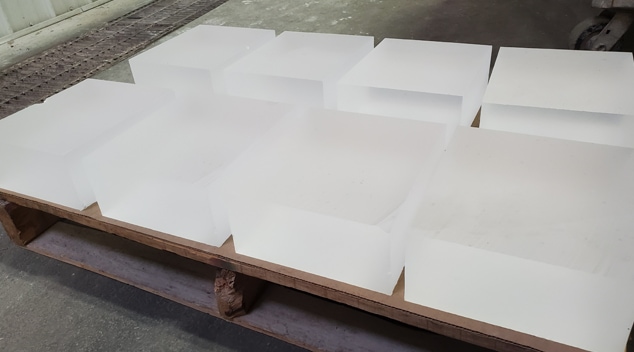

Swift Glass specializes in surface lapping and polishing services to achieve precise parallelism and extreme flatness rates on glass substrates.

Using computer-controlled and manually-operated machinery, Swift Glass is capable of handling both high and low volume projects.

Swift Glass offers single-sided and double-sided glass polishing techniques for components and precision optical parts. In addition to these polishing techniques, Swift Glass can also apply secondary coatings, such as anti-reflective and surface mirror finishes.

Learn about the medical glass that resists radiation’s effects >>

High Quality Materials

Swift Glass partners with trusted manufacturers to source and supply the most trusted materials in the medical industry.

- Borosilicate — Maintaining clarity and strength at high temperatures, this material is coveted for its functionality and affordability. Swift Glass offers standard borosilicate and infrared reflecting borosilicate (IRR borosilicate), as well as a number of branded varieties from major manufacturers like Corning and Schott.

- Quartz and Fused Silica — Quartz’s purity offers superior optical and thermal properties, which lead to high working and melting temperatures. These characteristics are ideal for medical laboratory equipment and semiconductor fabrication. Industrial fused silica is a popular material choice for many sight glass applications. Swift Glass supplies a variety of recognized brands of both quartz and fused silica.

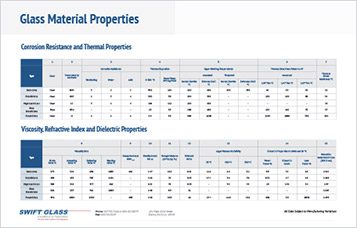

Is Your Glass Material Suitable for Your Application?

Find out with our Glass Material Properties chart.

Understanding your glass material’s thermal, chemical and physical properties is critical to ensure it can withstand the application’s use and environment.

Why Choose Swift Glass?

Swift Glass stocks a broad range of materials, which allows us to respond quickly to our customers’ needs. As an ISO-certified and ITAR registered company, we are proud to work with leading glass manufacturers such as Corning, Schott, GE and many more.

For more information about Swift Glass for medical applications, please visit our online library of standards and specifications.