Swift Glass is proudly ISO-certified and ITAR-registered, and has been working with military specifications for many years. Our production and materials meet a wide range of MIL-Specs and other strict industry specifications.

We offer full manufacturing services from prototyping to finishing and large scale production. The Swift Glass team can accommodate many different kinds of projects — short-run, large orders, simple projects or complex designs. We stock materials to meet a wide range of specifications and volume demands.

For military orders, a sample of the services we can provide are:

- Tempering/Chemical Strengthening

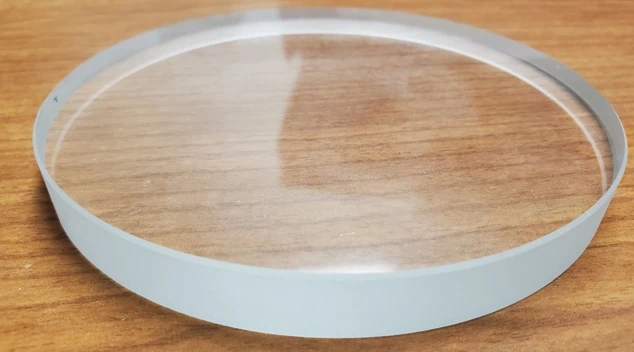

- Polishing

- Lapping

- Edging

- Edge Polishing

- Hole Drilling

- Waterjet Cutting

Materials

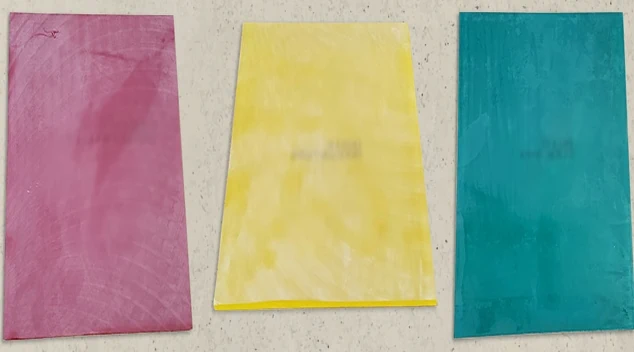

Below is a partial list of the materials Swift Glass can work with for your military application:

- 1737

- Anti-Reflective Glass

- Borofloat ®

- Ceramic

- Crown B-27

- Diamant

- Eagle 2000®

- Flashed Opal

- Fused Quartz

- Fused Silica

- Optiwhite

- Pyrex®

- Color Filters from Kopp, Schott & Hoya

- Soda Lime Float

- Starphire

- Rod & Tubing

- Vycor®

- X-Ray Shielding Lead Glass

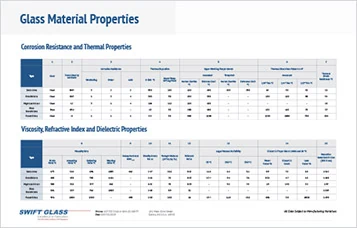

Is Your Glass Material Suitable for Your Application?

Find out with our Glass Material Properties chart.

Understanding your glass material’s thermal, chemical and physical properties is critical to ensure it can withstand the application’s use and environment.

Military Specifications and Regulations

Swift Glass offers a complete library of industry specifications and standards that includes information about each standard’s scope, specific requirements and applications. We have also assembled a Scratch-Dig Specifications Guide that indicates specs for MIL-REF 13830B.

All of our digital resources, including the guides above, are available for free download to maintain for your records and project planning.

Our glass experts have decades of experience working with sophisticated requirements and standards, and they’re eager to help deliver a glass solution with superior performance. Contact us today.

Quality is Our Mission

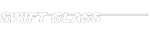

At Swift Glass, our optical components are held to the highest industry standard. We utilize the best equipment to ensure that your products are delivered with top-notch results.

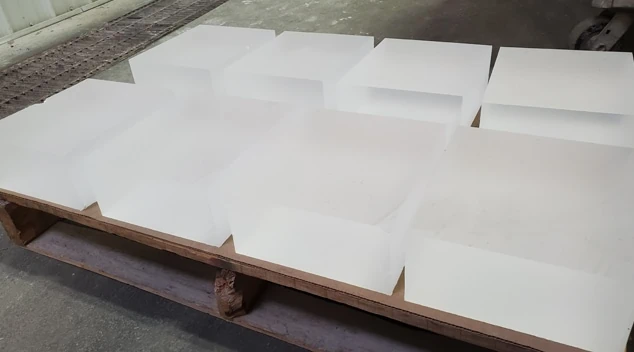

- Large plate lapping and polishing

- A Dark Room

- An Optical Comparator

- Optical Flats and an Optical Comparator

- Spectrophotometer

If you have questions about how to bring your next optical application to life, please contact a glass expert today.