What is Tempered Glass?

Leave a Comment

Uses and Applications of Tempered Glass

Tempered glass is immensely versatile and used in a wide variety of products. Tempered glass is used in automobile windows to make them less dangerous in the event of an accident. Tempered glass will break into smaller, duller pieces than annealed glass, making it the safer choice.

Tempered glass can also be found around the home in heat-adjacent objects such as stovetops, counters, ovens, and tabletops.

Essentially, toughened glass can be found anywhere that requires glass to withstand a great deal of wear and tear. It is specifically made to avoid injury in case of breakage and provides an ideal solution for:

- High-pressure windows

- Lighting products

- Explosion-proof windows

- Display cases

Related Processes and Specific Requirements of Glass Tempering

Tempered glass is created by heating glass. The tempering process involves a couple of steps:

- Heating. The glass travels through a high-heat tempering oven and is heated to approximately 1200 °F.

- Quenching. After it has been sufficiently heated, the glass is then quenched—or cooled down. The quenching procedure is very fast, and consists of several nozzles blasting the glass with cool air for several seconds. This is where tempered glass gets its strength—this dramatic shock causes the surface and edges to become compressed, and the inner layer to be in tension, thus strengthening the material by three to five times.

Tempered Glass Solutions from Swift Glass

In addition to our thermal tempering and chemical strengthening capabilities, our experienced specialists provide numerous services, including ultra-high pressure cold cutting, chemical strengthening, CNC machining, printing, drilling, and polishing.

To learn more about the benefits of tempered glass, download our eBook, “Creating Glass That Withstands Extreme Environments,” or contact us with any further questions.

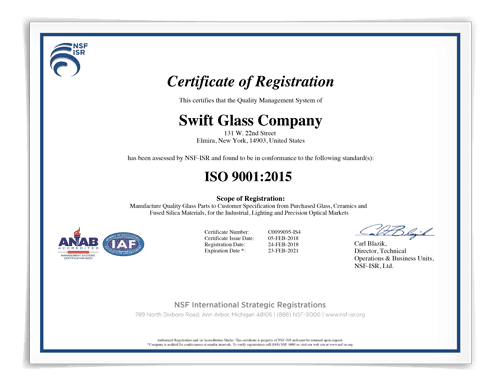

Swift Glass Is Proudly ISO 9001:2015 Certified

Leave a CommentAs part of our ongoing commitment to providing customers with the highest quality products and services, the team at Swift Glass is proud to announce that we have been ISO 9001:2015 certified for almost 10 years.

Here’s what this means for our customers.

What Is ISO 9001:2015?

Some of the best-known standards released by the organization are the ISO 9001 family standards, which provide industry professionals with guidance regarding quality management, specifically how to consistently meet customer requirements and improve product quality. These standards can also be adapted to accommodate the needs of different industries, such as ISO 13485 for medical devices and ISO/IEC 90003 for software engineering.

First published in 1987, ISO 9001’s current version was released to the public in 2015, making it ISO 9001:2015. Meeting the requirements set forth by this set of standards demonstrates the ability to deliver products of the highest quality and maintain standardized fabrication operations for reliable and consistent results.

At Swift Glass, Quality Is Key

How do Swift Glass’s quality standards meet and/or exceed ISO requirements?

Swift Glass has a long history of operating under the highest standards of quality and efficiency. In fact, for a number of years, we have been assessed by NSF-ISR and consistently shown that we conform to ISO 9001 standards. Each order we fulfill, whether it involves a single prototype or large quantities, is subjected to several levels of rigorous quality control. Among other assessments, we employ first-piece inspection, random sampling, and final checks before shipment.

What is Swift Glass doing on an ongoing basis to continue to live up to ISO standards?

From day to day, the Swift Glass team ensures all operations comply with ISO standards. If there is a failure in the procedure, we disassemble the system piece by piece to pinpoint the breaking point. In doing so, we are able to determine whether we should change the current approach and identify the path forward. To ensure that we fully understand the issue, we also review the standards externally.

How has this created the current culture at Swift Glass?

Our commitment to meeting ISO standards has fostered a problem-solving environment. We have developed multiple approaches to investigating problems, which gives us a deeper understanding of what is happening in the shop even when we aren’t on site.

How does this affect the products Swift Glass delivers to customers?

By following ISO procedures, workers can consistently achieve quality results. Our ISO 9001:2015 certification specifically focuses on ensuring quality during the manufacture of custom parts made from glass, ceramic, and fused silica material for the industrial, lighting, and precision optical markets.

Why is it important to customers for Swift Glass to be ISO 9001:2015 certified? How does it benefit them?

Our ISO 9001:2015 certification assures customers that we can and will consistently deliver high-quality products.

Swift Glass’s Offerings as an ISO 9001:2015 Certified Company

Swift Glass is a privately owned company that is a worldwide leader in manufacturing high-grade fabricated glass parts. Once we receive the design and spec information, our team is fully present to help select the best material for a project. Our extensive experience in the field and unstinting dedication to customer service and support helps us understand the parts we produce. This knowledge extends far beyond basic specifications, allowing us to meet each customer’s unique needs.

Our devotion to precision and quality is demonstrated by the fact that we are now ISO 9001:2015 certified and ITAR registered. For more information about these standards, download our ISO certificate.