If you’re in need of durable glass parts that can hold up in harsh environments, thermal glass tempering may give you the solution you need. As a highly beneficial glass strengthening treatment, thermal glass tempering is a suitable substitute for annealing when the latter could pose potential safety hazards. At Swift Glass, we can provide you with tempered glass products in various sizes and thicknesses to suit the needs of many applications.

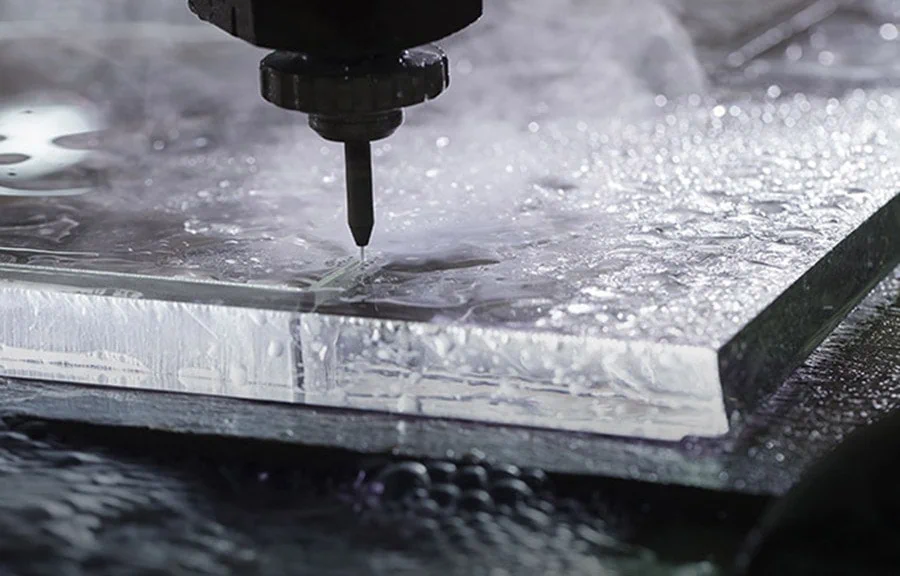

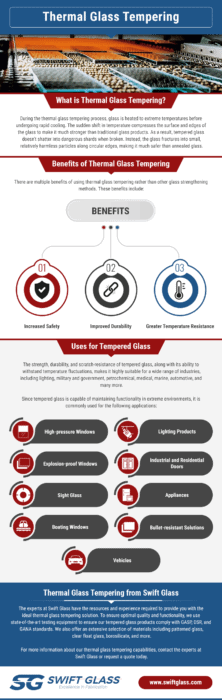

What is Thermal Glass Tempering?

During the thermal glass tempering process, glass is heated to extreme temperatures before undergoing rapid cooling. The sudden shift in temperature compresses the surface and edges of the glass to make it much stronger than traditional glass products. As a result, tempered glass doesn’t shatter into dangerous shards when broken. Instead, the glass fractures into small, relatively harmless particles along circular edges, making it much safer than annealed glass.

Tempering Process

1

Step 01

Based on application requirements, a glass material is chosen

2

Step 02

The glass travels through a high-heat tempering oven

3

Step 03

After it has been sufficiently heated, the glass is then quenched—or cooled down

4

This is where tempered glass gets its strength—this dramatic temperature shock causes the surface and edges to become compressed, and the inner layer to be in tension, thus strengthening the material

5

Tempered glass breaks into smaller, duller pieces than annealed glass, making it the safer choice

Benefits of Thermal Glass Tempering

There are multiple benefits of using thermal glass tempering rather than other glass strengthening methods. These benefits include:

Increased Safety

Unlike traditional annealed glass, tempered glass isn’t designed to shatter and form shards. Broken tempered glass forms small, circular pieces that make them safer in the event of breakage. This also makes broken tempered glass safer to clean and remove from an area without the risk of injury.

Improved Durability

Thermal tempering alters the glass’s composition to provide additional durability, strength, and resistance to scratching. This helps ensure that parts remain in working condition to prevent potentially costly equipment breakdowns and downtime.

Greater Temperature Resistance

Tempered glass is used in everything from aerospace and aviation applications to household items and laboratory equipment due to its ability to withstand higher temperatures and temperature fluctuations. Tempered glass is also often used to help meet fire code regulations in building construction along with many other applications requiring sufficient temperature resistance such as appliances, cookware, fire engines, drinking glasses, and more.

Uses for Tempered Glass

The strength, durability, and scratch-resistance of tempered glass, along with its ability to withstand temperature fluctuations, makes it highly suitable for a wide range of industries, including lighting, military and government, petrochemical, medical, marine, automotive, and many more.

Since tempered glass is capable of maintaining functionality in extreme environments, it is commonly used for the following applications:

- High-pressure windows

- Lighting products

- Explosion-proof windows

- Industrial and residential doors

- Sight glass

- Appliances

- Boating windows

- Bullet-proof solutions

- Vehicles

Thermal Glass Tempering from Swift Glass

Our versatility allows us to temper glass of various sizes and thicknesses. For products with thicknesses up to 1″, we can thermal temper glass at 34″ x 72″. For glass products with thicknesses ranging from 1″ to 2.375″, we can thermal temper glass up to 14″ x 14″.

At Swift Glass, we are proud to serve the following industries with our thermal glass tempering solutions:

- Automotive

- MarineLearn about the thermal glass tempering process and the various benefits that make it suitable for a diverse range of industries and applications.

- Military/Government

- Optical

- Lighting

- Semiconductor

- Building

- Energy

- Aerospace/Aviation

- Petrochemical

- Medical

For more information about our thermal glass tempering capabilities, contact the experts at Swift Glass or request a quote today.