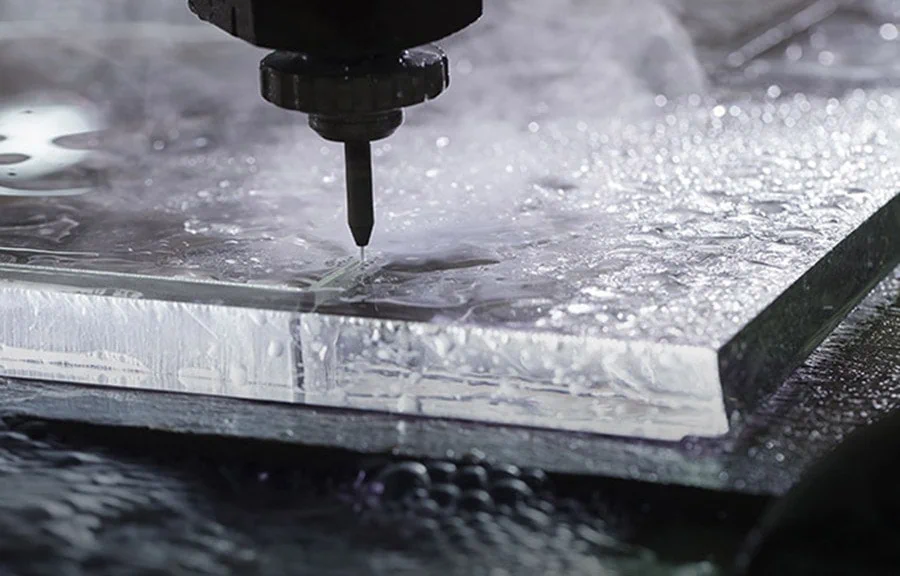

Swift Glass is proud to uphold a reputation of high precision hole drilling.

Whether you require drilling for glass doors, mirrors, furniture or something different, holes are essential elements that allow such products the ability to function properly for installation.

We can meet the exact specifications for a variety of industries, such as automotive, appliance, solar, medical, military, and many more. Swift Glass uses the most advanced, industry-compliant equipment available in today’s market. Our equipment meets ASTM, ASME, and military standards.

Our facility utilizes diamond tipped drill bits, which have been known for their ability to cut holes perfectly. With a (+/-) .01-inch tolerance, our superior machinery can cut through materials that are up to .75 inches in thickness.

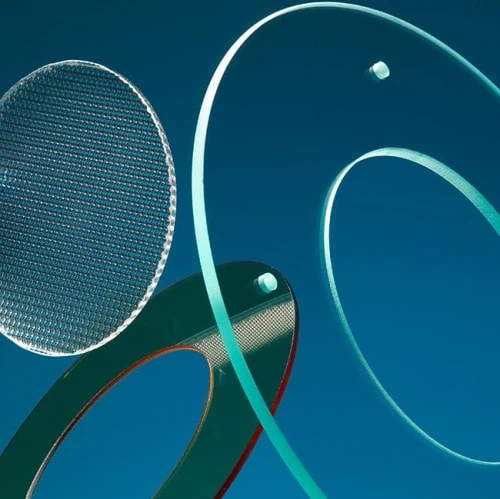

Large Material Selection

We carry a wide range of materials that are sure to meet your unique needs. Our offerings include:

Blue Vycor

- Borofloat®

- Fused Silica

- High Pressure Gauge Glass

- Borosilicate

- Quartz

- Soda-Lime

- Pyrex® Cylinders

- Bronze and Grey

- Composites

- Sight Glass

- Color Filters

- Furnace Observation Blue

- And Many More

Step-by-Step Solutions That Work

We are committed to working with our clients to create the most accurate results. Simply supply us with your CAD files, or other drawing files (JPG, PDF, BMP, GIF, etc.) and we will take it from there. From small, single unit projects to high volume productions, we can handle your most tedious drilling requests.

At Swift Glass, we provide our clients with:

- High quality and pin-point accuracy

- Friendly and personalized customer service

- Competitive pricing

- Versatile production capabilities

- Expert, glass industry knowledge

- Extensive selection of materials

- Speedy turnaround and delivery times

Ready to Get Started?

No matter what the job, we have the fabrication technology to complete the task. In addition, we are able to provide a range of prototyping solutions for our customers. If you have any questions about our services, please feel free to contact us today. Our amazing staff is ready to help you launch your next glass project.

Click on the table below to learn about our specifications.

Blue Vycor

Blue Vycor